-

Homepage

-

Seals and Gaskets

- Large seals

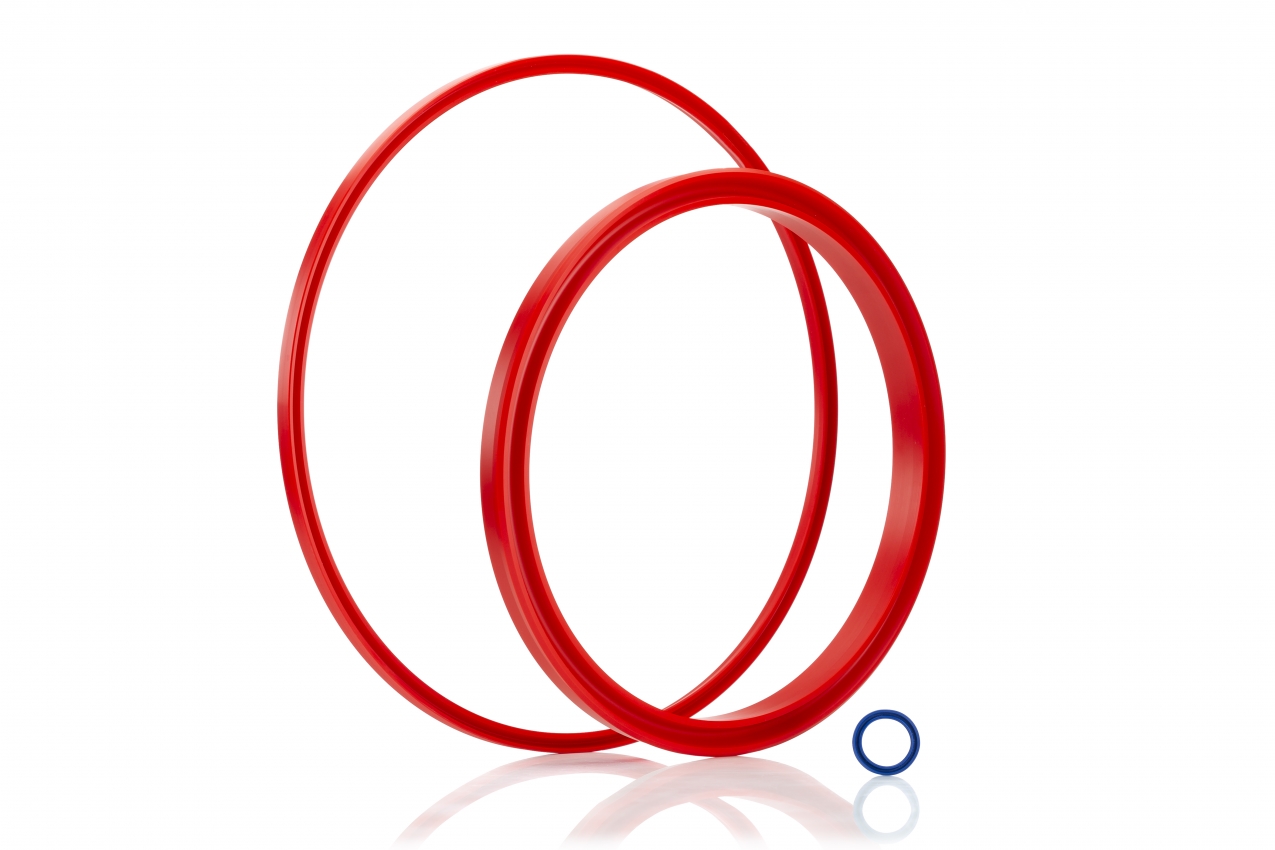

Large Seals - How are oversized seals actually constructed?

Large seals consist of a variety of raw materials and substances. Similar to standard seals, they are made from thermoplastic elastomers. Elastomers are highly elastic materials. They deform and stretch under pressure and tension, but revert back to their original shape. The most common elastomer materials include: - NBR - Viton® (FPM/FKM) - EPDM - Silicone: MVQ/VMQ (Methyl Vinyl Silicone Rubber) - H-PU Seals (PU) Seals and their elastomers have versatile applications. These are utilized, for instance, in flat seals and in dynamic seals within hydraulic cylinder systems. Dynamic seals, such as piston seals and rod seals, face extreme conditions such as high pressure and temperature. Due to these specialized requirements and operational conditions, O-rings are employed in these piston and rod seals to induce a pre-tension. Our K8 and S9 profiles, comprising an O-ring and a PTFE/Teflon or H-PU glide ring, can also be manufactured in large sizes and are used for applications such as large rolling mills. Generally, PU is the preferred sealing material for large-sized seals.

Large seal from 400 mm / 15,74 in - metal production and metal processing

Large seals over 400 mm / 15,74 in are frequently utilized in the metal industry, notably in metal production and metalworking. Extremely high standards are set for large seals in the metal industry. As machines increase in size, material and energy costs rise, and the employed large seals must endure extreme conditions. When an impact energy of 6 meters per ton / 62.42 lb/ft3 meets blanks heated to over 1,000 degrees Celsius / 1832°F, extreme forces impact all machine components. For such a challenging application, there is a need for special high-performance plastics with enhanced wear resistance, since linear movements involving significant force can more rapidly wear down machine components.

Large Seals Starting from 500 mm / 19,685 in in the Pharmaceutical Industry

Large seals over 500 mm / 19,685 in in the pharmaceutical industry (Sandoz) face various challenges. Purity and hygiene are of particularly high importance. In the pharmaceutical industry, it's crucial that high-quality seals prevent any contamination.

Chemical and thermal resistance must be absolutely ensured across different processes. At Kofler - Dichtungen, we consistently strive to meet these demanding standards.

Large seal up to 1000 mm / 39,37 in for power plants

Large seals up to 1000 mm / 39,37 in for power plants (GE Power) are mainly used for hot wind, gas and water pipes. The specially manufactured large seals are mainly installed in turbines, aggregates and pumps.

Here, too, enormous forces are exerted, whether by water and gas pressure or by extremely high temperatures.

High-pressure seal with a diameter of 2000 mm / 78,74 in - punching systems for the steel industry

High-pressure seals with a diameter of 2000 mm / 78,74 in are used, for example, in punching machines for the steel industry. As the name suggests, high-pressure seals are special sealing profiles that are subject to specific requirements due to the higher pressure. The manufacturing industry, such as the automotive or other press plants, generates a large quantity of materials using large punching machines. These special seals are typically made from harder elastomers (for example, NBR 90°)

Large seals for steel industry and metal presses

The application area for special high-pressure seals with large diameters includes, for instance, hydraulic metal presses in the steel industry. Particularly in the automotive industry, there is a trend towards designing increasingly larger machines, which in turn raises the requirements for the seals. Precise coordination of material composition here guarantees optimal operational safety and efficiency.

Shaft Seal for Shipbuilding and Maritime Navigation

Shaft seals are specifically employed in shipbuilding and maritime navigation. A shaft seal is a dynamic seal that must maintain the sealing force in balance during movements. Furthermore, shaft seals (for radial shaft seals) aim to minimize friction, thus preventing potential leakage—an essential requirement in maritime navigation.

At Kofler - Dichtungen, we promise absolute reliability for your custom seal solution! We can precisely manufacture the shaft diameter tailored to the installation spaces.

Large seals for wind turbines

Large seals for wind turbines withstand enormous stresses from changing wind forces. Maintenance costs and lifespan are factors significantly impacted by high-performance seals.

At Kofler - Dichtungen, we commit to the highest quality in selecting our raw materials and manufacturing processes, thereby ensuring the longevity of our application-specific special seals. We provide all seals from one source!

Used are, for instance, large seals and shaft seals such as:

- Shaft seals made of NBR (Nitrile Butadiene Rubber, resistant to lubricants and oils, and water up to approximately 100°C) or PU (Polyurethane)

- Axial seals from NBR

- Segmented flange seals made of POM (Polyoxymethylene, a sliding material noted for high compressive and extrusion strength, excellent machinability, very low water uptake, temperature resistance between -45°C and +100°C (-40°F and +212°F))

Hydraulic large seal

In hydraulic large seals, a distinction is made between dynamic (for example, in flange connections) and static seals. In the case of static seals, a component typically moves, such as a piston within a cylinder.

The hydraulic seal isolates the pressurized fluid from its environment. This minimizes the entry of air and moisture, prevents contamination, and stops the leakage of hydraulic fluid.

With our expertise in sealing technology, we can offer standard seals of this design as large-scale seals. Examples of hydraulic large seals include large construction machinery like the Belaz 75719 large dump truck, Komatsu 980E-4, Caterpillar Cat C175-20, Caterpillar 795F AC, Hitachi EH5000AC-3, tower cranes, mastic asphalt screeds, and many more.

Large Seal for Flange Joints - Petrochemical

The application-specific large seals for absolutely tight flange connections are a vital component for a smooth process in the chemical and petrochemical industries. On the part of occupational safety and also from an economic and environmental protection point of view, leaks must be avoided.

For special requirements, we at Kofler - Dichtungen offer special advice for seals. We will be happy to personally clarify with you which large seal is required for a reliable flange connection!

Sealing Materials for Large Seals: Large Seal Made of PTFE

PTFE stands for Polytetrafluoroethylene (Teflon), a special high-performance plastic. It is used in applications involving extreme temperatures. PTFE exhibits optimal chemical resistance against aggressive chemicals. Its low friction (sliding friction) and non-stick properties make these seals extremely slippery.

Large PTFE seals

- offer the highest chemical resistance,

- are water and grease repellent, and

- are biocompatible (physiologically safe).

Large seals made of HPU

Large HPU seals (HPU stands for hydrolysis-resistant polyurethane) are the most widely used material in the manufacture of hydraulic seals. Large seals made from HPU are:

- exceptionally wear-resistant and highly elastic,

- capable of withstanding high dynamic stresses,

- minimally gas-permeable.

Applications of large seals include metal processing, power generation, as well as the pharmaceutical and food industries. (FDA approved for specific HPU types)

Round cord rings and round cords

In the case of vulcanised round cord rings, round cords are cut to an appropriate length and endlessly vulcanised together in a butt joint. This innovative manufacturing process of sealing solutions enables economical production in precision quality. Thus, O-rings can be produced in large, non-standard dimensions.

Large Seals - Custom sealing solutions for industry

Kofler Seals supplies large seals in metric and imperial dimensions up to an outer diameter of 2,500 mm (98 in).

Large seals & special seals for the following areas and industries

Large seals for

- heavy industry

- hydrostatic presses

- energy technology / turbine construction

- petrochemicals

The material and profile selection is tailored according to the areas of application (hydraulics and pneumatics) or in coordination with the user. We offer a variety of hydraulic seals and pneumatic seals!