For increased production performance and safety for your large-scale project

Production performance and safety are top priorities in heavy industry. All heavy industry sectors have different demands and requirements. In addition, the machines, products and seals used are subject to the highest quality standards.

Kofler - Dichtungen has a wide range of different sealing solutions for any application. This is how we manufacture special seals, custom seals and gaskets and large seals, always with a focus on helping your project to a safe and optimized process.

Renowned international corporations from heavy and large-scale industry have therefore been relying on high-tech seals from Tyrol for a long time. The high quality seals of Kofler - Dichtungen and the unbeatable know-how have even spread to China. Our sealing elements are also exported to Asia.

Seals and gaskets for the metalworking industry

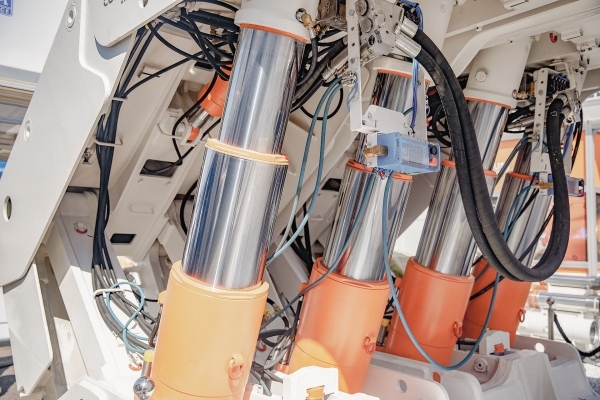

High demands are placed on seals in the metalworking industry. Due to the size of the machines, energy and material costs increase and large sums are at stake. In addition, seals in the metal industry have to withstand extreme conditions, such as high impact energies and extreme heat.

In this field of application, special high-performance materials are required that show increased wear resistance. This is because linear movement with a large force effect has a negative effect on the machine components, which is why wear and tear can occur more quickly.

An adequate seal is required here. As a seal expert for many years, Kofler - Dichtungen knows exactly which seal and gasket is the right one for your company.

Seals and Gaskets for the chemical industry

A smooth operation is crucial in the chemical industry. The application-specific seals must provide absolutely tight flange connections. Moreover, leaks must be avoided as much as possible to comply with occupational safety, economic, and ecological standards.

Our seals offer protection of the highest quality and ensure extended maintenance intervals.

Kofler - Dichtungen has been a long-standing partner in the heavy industry and thus knows exactly which seal your chemical plant needs to guarantee safety and quality.

Mining and Tunnel Construction - Our Expertise

Whether dealing with mud, water, sand, or rockfall, seals in mining and tunnel construction must conquer numerous challenges. This necessitates a sealing technology professional and special seal elements that exhibit high extrusion resistance, reliability, and quality.

Kofler - Dichtungen custom manufactures large seals with significant outer diameters and voluminous molded parts tailored to your requirements.

At Kofler - Dichtungen, we provide an extensive selection of seals and gaskets for the mining and tunneling sectors. For our loyal customers in these fields, our "just-in-time" deliveries are paramount. Kofler - Dichtungen considers just-in-time deliveries to be a special standard service!

Materials for heavy industry and large seals

Our large seals are made of a wide variety of materials and raw materials. Similar to standard seals and gaskets, they are made of thermoplastic elastomers, which guarantees the highest quality and stability.

- Elastomeric materials

- Silicone

- Stainless steel

- NBR, EPDM, silicone, FPM (FKM), PTFE (polytetrafluoroethylene), EPTFE, MVQ

36 Years of experience

Quality for over 30 years! Continuous innovation and outstanding service are the foundation of our success, on which we rely as a family-run business.

39.576 Various seals and gaskets

The range of seals and gaskets we have in stock is enormous. Our production of individual seals of all sizes and different materials makes us the expert in the sealing technology.

4.978 Customers Worldwide

We have been supplying industry leaders and specialists worldwide for over 30 years. Every day, new customers are added who rely on Kofler - Dichtungen Service.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Interesting Facts from Sealing Technology

Sealing Materials, and Elastomers: An Overview

Elastomers, as sealing materials, encompass various substances for specified applications in seal engineering. Elastomers are dimensionally stable and elastically deformable plastics. A prime example is rubber bands. While they maintain their shape, they also possess elastic characteristics and tensile stress due to an entropic effect (entropy elasticity). Elastomers are cross-linked through covalent bonds between molecule chains (macromolecules), similar to thermosetting plastics. This rubber-like elasticity occurs as the tangled polymer chains respond to tensile stress by stretching or disentangling.

What is an NBR seal?

What are NBR seals? Acrylonitrile Butadiene Rubber | Nitrile Rubber Elastomer with excellent mechanical properties - learn everything!

VITON® Seals and Gasket - What is the material FKM, FPM

What are Viton seals? An Overview of FKM and FPM | Fluorocarbon Elastomers for the Food, Pharmaceutical, Oil, Automotive, and Aerospace Industries - Discover Everything!

What are static and dynamic seals?