-

Homepage

-

Seals and Gaskets

-

Standard Profiles

- Shaft seal

Shaft seal - where can it be used?

Shaft seals, also known as rotary seals or Simmerings, are used in a multitude of applications within sealing technology, where moving parts need to be sealed. Typically, shaft seals are employed in areas requiring the sealing of rapidly rotating shafts (usually at high speeds) to ensure a transition into a metal housing with maximal sealing efficacy. Below are some common examples:

- Shaft seal in vehicles: wheel bearings, steering head bearings, differential, and transmission bearings (when related to vehicles, the shaft seal is often also termed a Simmering)

- Shaft seal in mechanical engineering: bearing positions in motors, transmissions, compressors, and pumps

- In electrical engineering: electric motors and generators

- In agriculture: tractors, agricultural machinery, and towed vehicles

- Shaft seal in power generation: gas turbines, steam turbines, coal power stations, and nuclear power plants

- In the chemical and petrochemical industry: processing units, refineries, and chemical plants

- Shaft seal in hydraulic and pneumatic systems (piston rod/hydraulic cylinder).

These are just a few instances; rotary seals find applications in many other fields as well.

Let us advise you; at Kofler - Dichtungen, we assist you in finding precisely the right seals for your specific needs!

Common types of Shaft Seals

Shaft seals are available in different designs, which differ in their construction, size and material. Here are some of the most common types of shaft seals:

- Radial shaft seal: This is one of the most commonly used designs. It consists of an annular body that is installed on a shaft and presses tightly against the housing bore.

- Axial shaft seal: This seal sits along the axis of a shaft and prevents liquids or lubricants from leaking out of the shaft.

- V-ring seal: This is a type of axial shaft seal that is designed in the shape of a “V” and presses tightly against the shaft.

- Metal Encapsulated V Seal: This is another type of axial shaft seal where the seal is enclosed in a metallic capsule.

- Clampable axial seal: This type of axial shaft seal ring is attached to the shaft by a clamping screw and offers easy assembly.

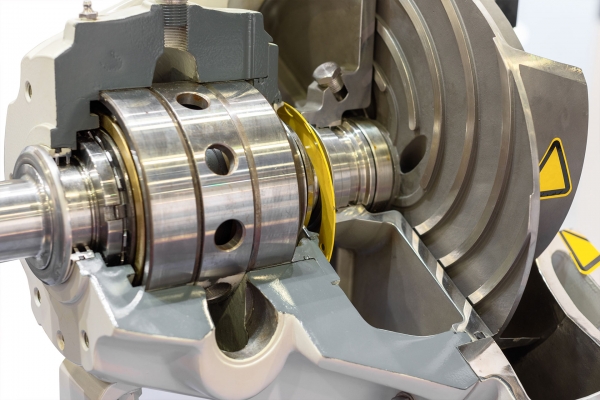

- Mechanical seal: This seal consists of a stationary inner ring and a movable outer ring that slide against each other to create a seal.

- Shaft seals are also available with sealing lip, protective lip or additional dust lip. The purpose of the sealing lip is to protect against dirt.

Each design has its own advantages and disadvantages, depending on the specific requirements of the application. It is important to choose the right design for a particular application to ensure a reliable and durable seal.

Axial Shaft Seal Ring

If dirt enters the area of the axial shaft, it can damage the lubricant, encourage corrosion, and lead to premature bearing damage. The axial shaft seal is the solution to prevent this. These seals are designed to withstand applications in which they are exposed to heavy contamination.

There are various types of axial shaft seals, including V-ring seals, metal-encapsulated V-seals, clampable axial seals, and mechanical seals.

Aside from the clampable axial seals, the axial shaft seals rotate with the shaft and act like protective discs. They can accommodate minor shaft misalignments and maintain the seal integrity even on uneven surfaces and in the presence of imbalances.

Radial shaft seal

Radial shaft seals are situated between moving and stationary parts, or between two components that move relative to each other. These seals comprise two primary elements:

A cylindrical outer casing with a tight fit that seals against the housing bore, and a sealing lip that dynamically and statically seals against the shaft.

The sealing edge is applied against the shaft's counter surface with a predetermined radial force.

Single-acting and double-acting shaft seal

The difference between single-acting shaft seals and double-acting shaft seals is quite simple to explain:

- Single-acting shaft seals only work against pressure from one direction and cannot work against pressure from the other direction.

- Double acting shaft seals are able to handle pressure from both directions as they each have a sealing surface on each side.

In addition, double-acting seals can withstand a higher pressure level than single-acting seals and are therefore more suitable for applications where high pressures are present.

Shaft Seal - Common Materials for a Rotary Seal

Shaft seals can be made from a variety of materials suitable for their applications. Here are some common materials for shaft seals:

- NBR (nitrile-butadiene rubber): a common material for rotary seals that is well resistant to mineral oils and lubricants

- FKM / FPM / Viton (fluorosilicone rubber): a high-temperature resistant material that is also resistant to aggressive media such as fuels, oils and chemicals

- EPDM (ethylene-propylene-diene rubber): a material with good resistance to water, steam and cold (high and low temperature range)

- PTFE (polytetrafluoroethylene): a material with excellent sealing properties and chemical resistance, but less flexibility than other materials

- Graphite Reinforced Rubber: a material that combines rubber with graphite fibers to provide better sealing and wear resistance.

The choice of the right sealing material depends on various factors, such as the requirements for the seal (e.g. chemical resistance, temperature resistance), the operating conditions (e.g. speed, pressure) and the media used (e.g. lubricants, liquids). Furthermore, you will of course also receive various hydraulic seals and pneumatic seals from us!

We at Kofler - Dichtungen are happy to advise you - material, design, variants and dimensions as well as assembly - Request advice now. Because under pressure we are the best!

What are the components of a shaft seal?

Of course, there are deviations depending on the design, manufacturer and intended use. In general, however, a shaft seal consists of the following components:

- Sealing lip: The sealing lip is the most important component of the shaft seal. It is made of rubber or other elastic material and provides the seal between axially moving or rotating shaft and housing.

- Metal housing or plastic housing: The fixed housing surrounds the sealing lip and protects it from damage. It also serves as a mounting point for the shaft seal. This part is also referred to as the stiffening ring. An elastomer outer sheath is often used for the stiffening ring.

- Spring: The spring, worm spring or tension spring ensures the uniform contact pressure of the sealing lip on the shaft. There are different spring constructions depending on the area of application. The pressure of the spring further improves the sealing effect.

- Dust lip: Some shaft seal rings have an additional dust lip or protective lip that prevents dirt and other contaminants from entering the housing and damaging the sealing lip. It nestles directly on the shaft surface.

- Housing sealing ring: Some shaft sealing rings have an additional housing sealing ring that prevents liquid or gas from escaping between the shaft sealing ring and the housing. This further increases the tightness of the entire system.

These components may vary depending on the manufacturer and field of application of the shaft seal. By carefully selecting the components and putting them together, an optimal seal and a long service life of the shaft seal can be ensured. We at Kofler - Dichtungen are happy to advise you on finding your ideal shaft seal!

What should be considered when choosing the right shaft seal?

When selecting the appropriate shaft seal, several considerations need to be taken into account, including the material, application purpose, dimensions, temperature, pressure, and environmental influences.

Material: The choice of material is dictated by the medium to be sealed and the surrounding environmental conditions. The most commonly utilized materials include nitrile, Viton / FPM / FKM, PTFE, silicone, and polyurethane.

Application Purpose: The specific use of the shaft seal determines the selection of both material and dimensions. Factors such as rotational speed, load, and the movement direction of the shaft seal are crucial.

Dimensions: Selecting the correct dimensions of the shaft seal is critical for achieving an effective seal. This includes size, inner diameter (shaft diameter), outer diameter, and width.

Temperature: The temperature or the range of temperatures of the medium being sealed and its environment influences the choice of shaft seal. Certain materials are better suited for higher temperatures than others.

Pressure: The pressure of the medium being sealed and the environmental pressure also affect the choice of shaft seal. Certain materials can withstand higher pressures better than others.

Environmental Influences: Factors such as exposure to chemicals, moisture, dust, and UV radiation can impact the selection of the appropriate shaft seal. It's essential to opt for a shaft seal that is resistant to the environmental challenges it will face.

Shaft Seal Design: The type of seal needed may vary, including axial shaft seals, radial shaft seals, cassette shaft seals, labyrinth shaft seals, V-ring shaft seals, or those incorporating an additional o-ring within the shaft seal structure.

All these factors are vital in choosing the correct shaft seal for your application to ensure effective sealing and longevity.

What should be considered when installing a shaft seal?

When installing shaft seals, the following points must usually be taken into account:

- Careful cleaning: Both the shaft and the housing must be cleaned carefully to ensure that there are no impurities or residues that could affect the seal.

- Correct alignment: The shaft seal must be correctly aligned to ensure optimal sealing. The sealing lip should point in the direction of the liquid or gas to be protected.

- Uniform contact pressure: It is important that the shaft seal ring is mounted with an even contact pressure on the shaft to ensure reliable sealing. Installation that is too loose or too firm can lead to leaks.

- Using the correct tool: Special tools should be used to assemble shaft seal rings to ensure that the shaft seal ring is mounted correctly and to avoid damage to the sealing lip.

- Observe the assembly instructions: It is important to follow the manufacturer's specific assembly instructions to ensure that the shaft seal is correctly assembled and that a reliable seal is ensured.

- Prevention of damage: Damage to the shaft seal should be avoided, as this can impair the seal. It is important not to deform or damage the shaft seal during assembly.

By carefully observing these points, an optimal seal and a long service life of the shaft seal can be ensured.

If you have any questions about the right shaft seal, correct assembly or materials - contact us. We at Kofler - Dichtungen are experts when it comes to seals!