-

Homepage

-

Seals and Gaskets

-

Standard Profiles

-

Shaft seal

- Radial Shaft Seal

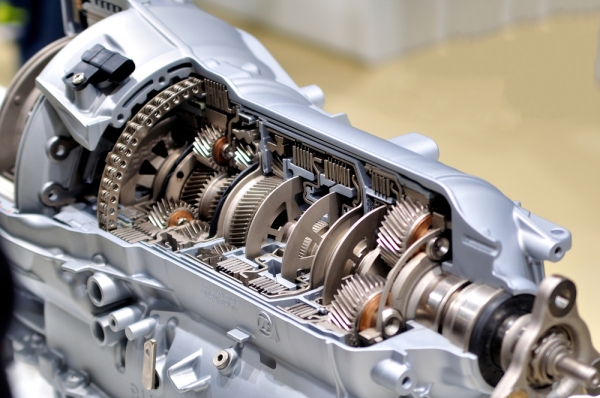

Radial shaft seals are predominantly utilized in rotating machinery such as motors, gearboxes, and pumps to prolong their lifespan and prevent leaks. They serve to seal rotating shafts across varying speeds and temperature ranges.

Radial shaft seals are positioned between moving and stationary parts, or between two parts that move relative to each other. These seals comprise two main components:

A cylindrical outer casing with a tight fit, sealing against the bore of the housing, and a sealing lip that dynamically and statically seals against the shaft.

The seal edge is applied against the shaft's mating surface with a predefined radial force.

Shaft seals are an essential element of sealing technology. Shaft seals are often referred to as Simmer rings, particularly in the automotive industry.

Generally, radial shaft seals differentiate or seal between two types of media. These are most frequently liquid and gaseous media, as well as potential environments with varying pressures.

What types of radial shaft seals are there?

There are various types of radial shaft seals, including standard radial seals, shaft seals, V-rings, and O-rings. Standard radial seals are the most commonly used and are available in different designs and materials. Shaft seals, also known as Simmerring seals, are employed to prevent the ingress of dirt and moisture into the ends of rotating shafts.

V-rings are conical seals designed to adapt to various shaft diameters. O-rings are circular seals placed in a groove on the housing or the shaft, offering effective leakage protection.

The Functions of Radial Shaft Seals

Radial shaft seals are utilized to prevent the escape of liquids or gases from the lateral movement of a rotating shaft. These seals are composed of an elastic material that wraps around the rotating shaft, equipped with a spring to apply uniform pressure on the sealing lip. This lip closely conforms to the shaft's surface, effectively preventing the leakage of fluids or gases into the surrounding area. Used in rotating machinery such as engines, gearboxes, and pumps, radial shaft seals serve a crucial role in avoiding leaks and prolonging the equipment's lifespan. Often, they act as a vital connection between a stationary metal housing and a rotating shaft or axle

Requirements for radial shaft seals

Radial shaft seals must meet several requirements to ensure effective sealing. They need to be chemically resistant to the media they are sealing, provide adequate abrasion protection, and possess high thermal stability.

Furthermore, they must be corrosion-resistant and withstand wear and aging to guarantee a long lifespan with optimal sealing performance.

The sealing lip also needs to be flexible enough to closely adhere to the surface of the rotating shaft while maintaining enough rigidity to prevent tearing or dislodging.

Additionally, the design of the radial shaft seal should be straightforward to install, to reduce labor costs and assembly time.

Structure of radial shaft seals

Radial shaft seals are made from an elastic material, such as Nitrile (NBR), Fluorocarbon rubber (FKM/FPM/Viton), or PTFE. Typically designed as a ring, they feature a sealing lip that snugly wraps around the rotating shaft, and a spring or tension spring that presses the sealing lip against the shaft. Depending on the requirements and application, the sealing lip may be executed as either a radial or axial type (Axial shaft seal).

Some radial shaft seals also come with a metal or plastic casing, which protects the sealing lip and makes installation easier. Additionally, certain models include an extra protective lip to block the ingress of dirt, gases, and moisture into the system.

Radial shaft seals are available in standard, special, and custom designs, as well as in unique materials at Kofler - Dichtungen. Feel free to request a personal consultation!

Commonly used materials for radial shaft seals

Radial shaft seals can be made from a variety of materials suitable for their applications. Here are some common materials for radial shaft seals:

- NBR (nitrile-butadiene rubber): the material NBR is common for rotary seals, as it is resistant to mineral oils and lubricants

- FKM / FPM (fluorosilicone rubber, also Viton): a high-temperature resistant material that is also resistant to aggressive media such as fuels, oils and chemicals

- EPDM (ethylene-propylene-diene rubber): a material with good resistance to water, steam and cold

- PTFE (polytetrafluoroethylene): a material with excellent sealing properties and chemical resistance, but less flexibility than other materials

- Graphite Reinforced Rubber: a material that combines rubber with graphite fibers to provide better sealing and wear resistance.

The choice of the right sealing material depends on various factors, such as the requirements for the seal (e.g. chemical resistance, temperature resistance), the operating conditions (e.g. speed, pressure) and the media used (e.g. lubricants, liquids).

It should also be mentioned that radial shaft seals are often made of combined materials, since the demands on the connection to the fixed housing or the housing bore are different from those to the rotating shaft, where, for example, a PTFE sealing lip makes sense, while other parts of the seal have an elastomer outer jacket. A stiffening ring as well as a worm spring or seals with an additional dust lip can also be used to ensure ideal sealing and maximum service life.

We at Kofler - Dichtungen are happy to advise you - material, design, variants and dimensions as well as installation - just contact us. Because under pressure we are the best!

Tips for purchasing radial shaft seals

When buying radial shaft seals, there are a few important factors to consider. First of all, the requirements of the scope of application should be precisely defined in order to select the appropriate type of seal and the suitable material. It is important to know exactly the size and dimensions of the seal space to ensure that the selected radial shaft seal fits. The operating conditions, such as temperature and pressure, must also be taken into account. It is advisable to buy radial shaft seals from reputable manufacturers who can guarantee quality and reliability.

In addition to the temperature range, the desired outer diameter as well as the inner diameter and the circumferential speed must also be taken into account.

It is also advisable to purchase a sufficient number of seals to allow replacement if necessary. Finally, it is important to carry out regular inspection and maintenance to ensure optimum performance and a long service life of the radial shaft seals.

Conclusion on radial shaft seals

Radial shaft seals are essential sealing components used in rotating machinery and systems to prevent the ingress of dirt, moisture, and other contaminants, as well as to retain any media that have leaked within the system. Their purpose is to offer an effective and durable barrier against leaks, thereby extending the lifespan of the machinery.

Various materials, including NBR, FKM, PTFE, and metal, are available for radial shaft seals, with the choice depending on the specific requirements of the application. It's crucial to consider the size and dimensions of the sealing space and the operational conditions, such as temperature and pressure, when selecting the appropriate radial shaft seal. Moreover, purchasing radial shaft seals from reputable manufacturers is recommended to guarantee quality, maximal sealing effectiveness, and reliability.

Regular inspection and maintenance of radial shaft seals are indispensable for ensuring optimal performance and longevity.

Frequently Asked Questions (FAQ)

What is a radial shaft seal?

A radial shaft seal is a sealing component used in rotating machinery and equipment to prevent the penetration of dirt and moisture into the system and to keep the escaped liquid in the system. The seal is cylindrical and is inserted into a recess on the housing or on the component, where it ensures a permanent seal between the rotating shaft and the stationary part of the system.

How to choose the right radial shaft seal?

In order to select the correct radial shaft seal, the dimensions of the seal space as well as the operating conditions such as temperature and pressure must be taken into account. The choice of material depends on the specific requirements of the application. Regular inspection and maintenance of the radial shaft seals is essential to ensure optimum performance and long service life. It is recommended to buy radial shaft seals from reputable manufacturers to ensure quality and reliability.

How to install a radial shaft seal?

The installation of a radial shaft seal necessitates meticulous preparation and alignment of the shaft, along with the precise positioning of the seal element within the housing. Special tools should be used to apply the seal gently and uniformly to the shaft. To prevent damage to the seal element, care must be taken not to exert pressure on the lip area with the tool.

After installation, the seal's fit must be verified for correctness. A correctly installed radial shaft seal ensures a durable seal, effectively preventing the escape of fluids and lubricants from the system.

How to maintain a radial shaft seal?

Regular maintenance is important to ensure the performance and service life of radial shaft seals. It is important to check the sealing ring for wear and tears and make sure it is properly seated on the shaft. Contamination and impurities must also be removed. If the sealing ring is worn or cracked, it must be replaced. It is advisable to also check other components of the system such as bearings and sealing surfaces during maintenance to ensure optimal performance.