-

Homepage

-

Sealing knowledge

- What is an NBR seal?

NBR Seals and Gaskets by Kofler - Dichtungen

Nitrile rubber (NBR) is one of the most widely used sealing materials for industrial applications involving oils, fuels, and hydraulic fluids. At Kofler – Dichtungen, we offer expert knowledge and a wide range of NBR seals and gaskets tailored to your specific requirements. On this page, you’ll find everything you need to know about the properties, advantages, and areas of application of NBR – directly from your sealing specialists.

NBR - What does nitrile butadiene rubber mean?

NBR (nitrile butadiene rubber), is a synthetic copolymer, sometimes referred to by its acronym NBR or simply nitrile rubber, is a high-performance polymer widely used for seals and gaskets. It’s also known under the term Perbunan. The meaning of NBR comes from its main components: acrylonitrile and butadiene. This combination gives the material its strong mechanical properties and broad application range in sealing technology and adhesives, where secure bonding and sealing are both required. NBR is also known as Buna-N or simply nitrile rubber.

The NBR material (nitrile butadiene rubber) is a modern elastomer and polymer that stands out for its excellent mechanical properties. This synthetic rubber combines high abrasion resistance, strong tensile strength, and reliable elasticity across a wide temperature range. Thanks to its adjustable acrylonitrile content, NBR seals and gaskets achieve a low compression set, making them an ideal choice for various sealing applications.

Its very good chemical resistance makes NBR an ideal material for seals, applicable for flat gaskets, O-rings, shaft sealing rings e.g., Simmering seals as well as hydraulic seals and pneumatic seals, seal kits and custom seals. In the following post, you will learn everything about NBR as a sealing material. Also, read our sealing knowledge and comprehensive overview of sealing materials.

NBR - Properties of NBR rubber as a sealing material

NBR (acrylonitrile-butadiene rubber) is a modern elastomeric material with good resistance to a wide variety of chemicals. NBR rubber is compatible with oils and fats such as fuels, diesel, kerosene, aliphatic hydrocarbons, natural gas, as well as diluted acids, alkalis, and alcohols. Thus, NBR demonstrates resistance to gasoline, making NBR seals generally gasoline-resistant.

The application range of NBR in terms of temperature is broad, offering good low-temperature flexibility down to around -30°C and heat resistance up to +120°C. Depending on the acrylonitrile content, NBR can be used from -30°C to +120°C (-22°F to +248°F).

The mechanical properties of NBR are also excellent. It has significant tensile strength and shows a minimal permanent set under elastic deformation.

Because of these properties, NBR seals are ideally suited for a variety of seal types such as hydraulic seals or pneumatic seals. Often used alternatives to NBR material include HNBR, EPDM and FKM. In comparison, FKM is less resistant to weathering, less heat-resistant, and not suitable for use with brake fluids.

EPDM, in contrast to NBR, has the drawback of having poorer resistance to fuels (gasoline, diesel, kerosene, mineral oils) and solvents. Also, EPDM is not suitable for use in the food industry.

NBR Seals and Gaskets - When should NBR not be used?

NBR is relatively sensitive to UV radiation and ozone, and therefore, it should not be exposed to these elements. If the requirement profile for mechanics, temperature, and chemical resistance still favors the use of NBR, one should expect an increased need for maintenance due to reduced operational lifespans.

NBR is incompatible with aromatic hydrocarbons such as benzene and toluene, as well as solvents like acetone (ketones), acetic acid esters, and chlorinated solvents including chloroform and dichloromethane.

Adjustment of the Properties of NBR Material

The first version provided is already clear, precise, and grammatically correct. However, to ensure the translation is as polished as possible, here is a slightly refined version:

The NBR material is available in various grades. The acrylonitrile content is adjusted to fine-tune its properties, enabling optimal application in specific areas. NBR is the material of choice for high operating temperatures!

A higher acrylonitrile content in the material extends its application range to higher temperatures, allowing the material to maintain its advantageous mechanical properties up to +120°C (+248°F). For lower temperatures, the acrylonitrile content can be decreased.

The acrylonitrile content also influences the chemical resistance. An increased amount of acrylonitrile enhances the material's resistance to oils, fats, fuels, and aliphatic hydrocarbons.

In addition, NBR is utilized with different material hardness levels, expressed in degrees Shore A. The two most common forms are 70° Shore A and 90° Shore A, with higher hardness providing greater pressure resistance.

What are the advantages of an NBR seal?

The mechanical properties of NBR are particularly advantageous. It is low-wear and therefore well suited for dynamic seals, e.g. as a hydraulic seal or pneumatic seal.

Chemical resistance is another great advantage of NBR. Due to the polar chemical groups in the polymer, it easily withstands non-polar substances such as fuels, oils and fats.

In addition, NBR is also available in a food-safe version and is therefore physiologically harmless. Please ensure that the respective seals are always marked with a respective certificate (e.g. FDA), as not every NBR is automatically food-safe. Due to its resistance to oils and diluted acids, it can be used in beverage production (water, dairy products and fruit juices).

It is also used in seals and machine parts in food production.

NBR has a high gas tightness, so that it can also be sealed against substances with a high volatility such as gasoline and also, for example, natural gas.

The advantages of NBR seals at a glance:

- high Shore hardness (high material hardness)

- high pressure resistance

- high temperature resistance up to +120°C (+248°F)

- outstanding mechanical properties

- strong resistance to chemical compounds such as: silicone or silicone oil, mineral oil, propane, butane, fuels such as diesel, petrol or kerosene, alcohol as well as acids and bases (alkalis)

Important: NBR does not have ozone resistance, materials such as EPDM seals are suitable here.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

NBR material - advantages over other elastomers

Nowadays, a variety of elastomers are available. Why should you choose NBR?

NBR, for example, outperforms CSM (chlorosulfonated polyethylene), CR (chloroprene rubber), and natural rubber in terms of chemical resistance and fat and oil resistance. If the elastomer comes into contact with fuels or oils during your application, you should consider NBR.

In addition, NBR is considered an inexpensive all-rounder among sealing materials, which is used as standard for most O-rings, for example.

What is XNBR and how does it differ from standard NBR?

XNBR (carboxylated nitrile butadiene rubber) is a modified version of standard NBR, enhanced with carboxylic acid groups in its polymer chain. This chemical modification significantly improves its abrasion resistance, tensile strength, and tear resistance, making XNBR particularly suitable for dynamic sealing applications and environments with high mechanical stress.

Compared to conventional NBR, XNBR maintains the excellent oil and fuel resistance of nitrile rubber while offering greater durability under frictional loads. Common uses include seals, gaskets, diaphragms, and hydraulic components exposed to abrasive media or high wear. However, like NBR, XNBR is still sensitive to ozone and UV and should be protected in outdoor use.

What does "carboxylated" mean in sealing materials like XNBR?

The term carboxylated refers to the chemical modification of a polymer by adding carboxylic acid groups (–COOH) to its molecular structure. In sealing materials like XNBR (carboxylated nitrile rubber), this modification leads to improved mechanical strength, abrasion resistance, and tear resistance.

By introducing these polar carboxylic groups, the polymer chains can form additional crosslinks, resulting in a tougher and more durable elastomer. This makes carboxylated materials ideal for dynamic sealing applications, where high mechanical stress or repeated movement occurs. Despite these enhancements, carboxylated rubbers retain the oil and fuel resistance typical of standard nitrile rubber.

Where are NBR seals used?

The properties of NBR make it a very versatile material that can be used in many areas.

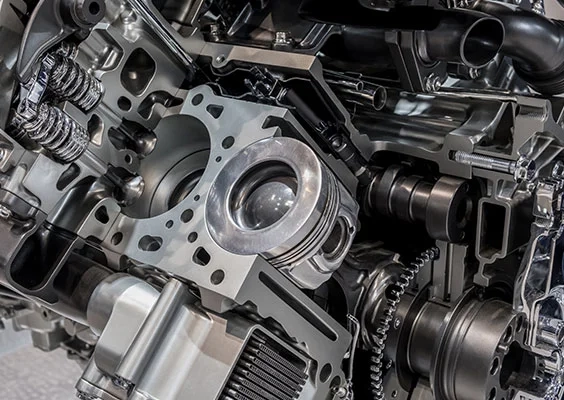

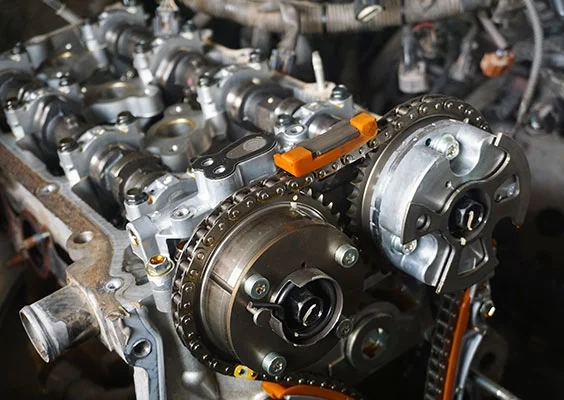

Due to its resistance to oils and fuels, NBR is often the material of choice in the automotive industry, for example in seals, gaskets, fuel hoses and hydraulic hoses. For example, NBR O-rings show resistance to gasoline and diesel. NBR flat gaskets are also used. In general, NBR is very popular in industry, e.g. in mechanical engineering as a hydraulic cylinder seal.

The partially physiological safety also makes it possible to use it in research and medicine. As a glove material, NBR is an excellent alternative to allergenic latex gloves. A wide variety of small parts are also manufactured from NBR in the chemical industry and pharmaceutical research, as they have good chemical resistance.

Standard NBR Seals and Custom-Made Seals

In the NBR Shop from Kofler – Dichtungen you can get rubber seals made of NBR according to your needs. We supply you with standard seals and gaskets such as flat gaskets, profile gaskets and O-rings.

In order to meet the most demanding applications, we also offer custom NBR industrial seals: we manufacture seals according to your wishes and specifications. Contact our seal experts today, they will be happy to hold a consultation with you and advise you on your options, so that you receive a custom-made NBR seal. You can have your seals made.

Send us the article number or the data sheet of your NBR seal, so we can keep production and or delivery times short! Follow Kofler - Dichtungen also on LinkedIn for information and updates.