Maximize productivity and efficiency, eliminate loss

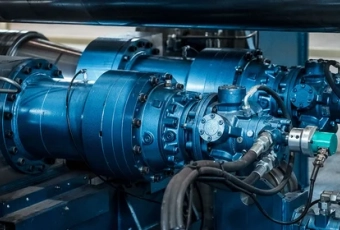

Similar to mechanical engineering, seals and gaskets are essential components in plant construction. Without them, neither completion nor commissioning of plants would be possible.

Furthermore, the proper sealing of components can significantly enhance the productivity and efficiency of plants by deliberately preventing unnecessary interruptions, downtime, and financial losses.

Kofler - Dichtungen is actively committed to assisting you in this regard. Through the development of sustainable and high-performance sealing solutions, we enable our partners to optimize processes, reduce costs, and increase safety.

Custom seals and gaskets or standard seals for your system

Kofler - Dichtungen is known for its innovative sealing technology. We can rely on a wide range of geometries and materials - from standard seals to custom gaskets to complex special seals.

Needs and requests can be met in the shortest possible time thanks to years of expertise tailored to the customer's wishes, which also effectively minimizes your warehousing.

Regardless of which systems you build, be it punching or robotics systems, we have the sealing technology for every specific case!

High-Quality Materials for Your Facility

In order to ensure the best possible efficiency and safety for your facility, Kofler - Dichtungen exclusively uses high-quality and industry-compliant materials.

- PTFE

- EPDM

- Elastomer

- PU, HPU, NBR, MVQ Silicone, POM, PEEK

Our products for your plant construction

Our products for plant construction range from custom seals, specifically tailored to your plant and your wishes, and special seals to standard seals and gaskets. We also offer the installation of complete sealing sets, specially designed for your hydraulic applications.

36 Years of experience

Quality for over 30 years! Continuous innovation and outstanding service are the foundation of our success, on which we rely as a family-run business.

39.576 Various seals and gaskets

The range of seals and gaskets we have in stock is enormous. Our production of individual seals of all sizes and different materials makes us the expert in sealing technology.

4.978 Customers Worldwide

We have been supplying industry leaders and specialists worldwide for over 30 years. Every day, new customers are added who rely on Kofler - Dichtungen Service.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Insights into Sealing Technology

Sealing Materials, and Elastomers: An Overview

Elastomers, as sealing materials, encompass various substances for specified applications in seal engineering. Elastomers are dimensionally stable and elastically deformable plastics. A prime example is rubber bands. While they maintain their shape, they also possess elastic characteristics and tensile stress due to an entropic effect (entropy elasticity). Elastomers are cross-linked through covalent bonds between molecule chains (macromolecules), similar to thermosetting plastics. This rubber-like elasticity occurs as the tangled polymer chains respond to tensile stress by stretching or disentangling.

What are EPDM seals?

What are HPU seals?

What are HPU, HPU solid and HPU-MOS2 seals? HPU stands for hydrolysis-resistant PU and is a further development of polyurethane (PU, DIN abbreviation: PUR)

Sealing Technology – All about Seals and Gaskets

Sealing technology all about seals and gaskets ✓ Which standard profiles, special seals to fit your application - read more now!

Materials

Here you will find a brief description of the standard materials used. Of course, Kofler - Dichtungen also processes most materials and sealing materials that are not listed here.