-

Homepage

-

Seals and Gaskets

-

Standard Profiles

- Wiper seal

Scrapers - What Exactly is a scraper seal?

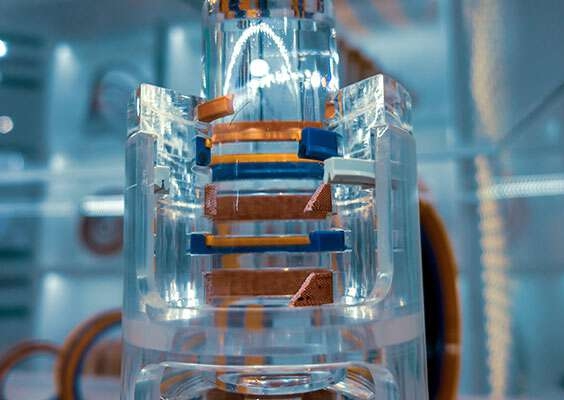

Scrapers (also known as scraper rings, dirt scrapers, or wiper seals) are the outermost element of a seal system (hydraulic cylinder seal). As such, they are not subject to any notable hydraulic pressure. Scrapers prevent the ingress of dirt, water, and moisture into hydraulic cylinders and pneumatic systems by wiping the entering piston rod through a wiper lip. An example of this application is with compressed air refrigeration dryers like those from manufacturer Schneider Airsystems.

Double-acting Scrapers as Hydraulic Seals

Double-acting scrapers also remove hydraulic fluid from the extending rod, as a too-thick residual film can cause leakage. Furthermore, contaminants are more likely to adhere to a thick liquid film.

Seals for the industry must withstand particularly high demands. Industrial seals satisfy all requirements for long service life, high sealing integrity, and resilience under heavy loads. We meet your requirements with our technical expertise, high-quality materials, and continuous quality control.

Scraper - Which scraper rings are available for purchase?

Scrapers and scraper rings are available for convenient online purchase at Kofler - Dichtungen. Single-acting scrapers are often designed as lip rings or special groove rings, but our range also includes special profiles.

Double-acting scrapers possess the additional functionality of removing any residual oil film, thus enhancing the sealing system. This enhancement is achieved through a second sealing lip (double scraper). We also offer pre-tensioned double-acting scrapers, where a PTFE sealing element is pressed against the piston rod by an O-Ring. This feature ensures exceptionally high tightness with favorable sliding properties.

For metal-reinforced scrapers (or steel scrapers), the scraper is housed within a metal cage or incorporates metallic stiffening rings. Metal cages are created as vulcanized metal angle rings. The design of these scrapers with a metal adherence feature provides minimal attack surface for corrosive hydraulic media. Stiffening rings are vulcanized into the elastomer body, ensuring dimensional stability and securing the functional positioning of the scraper. This type of scraper seal is specifically utilized in open mounting spaces.

For pneumatic system seals, in scenarios where the scraper must not rust or when special sizes are required, we produce and provide our unique metal-free, alternative scrapers.

Scrapers for Hydraulic Seals

Unlike the hydraulic seal (What is a hydraulic seal?), for these scrapers, we utilize a plastic cage made from technical polymers such as POM (Polyoxymethylene).

If you need assistance in selecting the right design for your requirements, we are happy to provide advice and manufacture custom seals and made-to-measure seals for your specific application.

Scraper materials in sealing technology

Scraper materials must be selected in sealing technology depending on the application and operational area. Scrapers are exposed to environmental adversities and keep dirt, dust, moisture, chips, etc., away from sensitive components. Withstanding these conditions and temperature ranges is only possible by using high-performance materials.

Common materials for scrapers include:

- PU (Polyurethane, TPU),

- NBR (Nitrile Butadiene Rubber),

- PTFE (Polytetrafluoroethylene),

- PTFE Compounds (composite materials made of PTFE and bronze, carbon, or MoS2), and

- Viton®, FPM, FKM seals (Fluororubber).

Our sealing materials cover a wide range of hardness, elasticity, temperature resistance, and chemical resistance. Thus, we can offer you a tailor-made solution for almost every application area.

If you need assistance choosing a suitable material, you can contact us at any time. We are happy to provide advice with our technical expertise.

Buy Scrapers for various installation spaces online

In order to choose the correct geometry of the scraper, you need prior knowledge of the type of installation space. In principle, a distinction is made between open installation spaces and closed installation spaces.

In open installation spaces, metal scrapers are pressed in, whereas in closed installation spaces scrapers made of elastomers (PU, NBR) or PTFE can be installed. Scrapers (single-acting) and custom-made products are possible.

Scraper - The correct assembly of a scraper seal

The installation of a scraper generally depends on the design. In general, it is important to ensure that the installation space is properly prepared. It must be free of dirt and without burrs or sharp edges. These can destroy your scraper. The scraper can now be pressed into the installation space.

Steel scraper assembly

Here, we demonstrate how to install a steel scraper (scraper with a metal cage). Typically, this involves using a lever press. However, we will show you how it can also be accomplished without such a press. The only tools you'll need are a plastic ring and a plastic hammer. The diameter of the plastic tube must match the metal cage and must not rest on the rubber lip to prevent damaging the scraper seal. Firstly, ensure cleanliness and the absence of sharp edges. Verify that the other seals have been correctly installed. Then position the scraper in the installation space and align the plastic tube against the metal cage. The lip of the scraper must remain unobstructed. By using measured hammer blows, you can now insert the metal cage into the installation space. Various debris scrapers with open grooves come with an integral metal reinforcement for insertion into open installation spaces

Order complete seal set online

Are you in search of a complete hydraulic cylinder seal kit for hydraulic seals, including rod seals, piston seals, guide rings, and O-rings? At Kofler - Dichtungen, you can order not only wipers but also complete seal kits, as well as flat gaskets, shaft seals, or Simmerring seals. Our assortment also includes rotary seals and V-ring seals. We design a seal kit specifically tailored to your needs and applications, or you can select from our standard profiles.

Do you have questions? Contact our team of experts.

Production goods

Single-acting scrapers and double-acting scrapers

The application areas and sealing systems vary, hence the need for different types of scrapers - single or double-acting scrapers. What is the difference between single-acting and double-acting scrapers?

Single-acting scrapers are designed to keep dirt and contaminants out from the exterior. Double-acting scrapers, however, have the additional function of improving the sealing system and removing the remaining residual film.

How is a scraper constructed?

The structure of the scraper is clearly defined. The special shape of the dirt lip prevents the penetration of unwanted foreign bodies. In cylinders and valves, scrapers prevent the formation of grooves, protect the guide parts and extend the service life of the seals and other components. Wipers are therefore extremely important for a long-lasting function.