-

Homepage

-

Sealing knowledge

- Pneumatic seal

Pneumatic seals

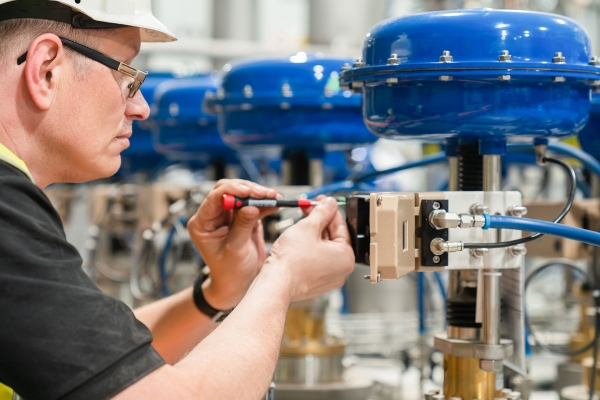

Pneumatic seals or pneumatic systems are utilized across various sectors, especially where robotics and mechatronics are deployed, thus automating workflows or in cases where a hydraulic system would be impractical. And where pneumatics is involved, a high-quality seal is essential! A pneumatic seal must meet stringent requirements, as it, like its counterparts in hydraulics, operates within dynamic systems. This article offers an overview of pneumatics' current applications, types of pneumatic seals, the requirements for pneumatic seals, and the materials employed for them. Did you know that approximately 60 percent of seal issues arise due to the use of incorrect materials? By employing the latest designs and materials, we cater to the needs of every industrial field.

Where is pneumatics used?

Pneumatics is indispensable in a wide variety of industries. Pneumatic cylinders, pneumatic valves, vacuum systems or grippers work with air pressure. Pneumatic systems are needed in medical technology and material handling as well as in robotics, drive and transport. Pneumatic systems are installed, for example, in air brakes of trucks and buses.

Air-filled tyres, pneumatic mail and pneumatic tools such as nailing machines, impact wrenches or pneumatic grinders are also dependent on pneumatics. Pneumatics are also used in mechanical engineering, process engineering, the mineral oil industry, mining and food production.

What is absolutely relevant is that pneumatic systems run perfectly: the right sealing technology – without pneumatic seals, which ensure the proper functioning of the systems, pneumatic systems would not run in industry. Precisely for this reason, it is important to maintain these spare parts well and replace them early. Because: Leaking pneumatic seals significantly increase the risk of downtime and production losses.

Pneumatic seals – dynamic seals

Pneumatic seals, like hydraulic seals, fall into the category of dynamic seals. In contrast to pneumatics, which operates with air, hydraulics use a liquid medium. (What exactly are hydraulic seals?) Dynamic pneumatic seals are utilized in moving systems and must withstand rotating, reciprocating movements, and often high speeds.

These dynamic seal types are also sought after when customers require solutions that surpass standard products. Just as in hydraulics, pneumatics also demands sophisticated sealing technology. An overview of pneumatic sealing systems: - Rod seals - Piston seals - Rod seal-wiper combinations - Static seals - Scrapers - Guide rings and damping seals (e.g., for pneumatic shock absorbers)

Rod seal

The function of the rod seal is the same in pneumatics and hydraulics: it seals the exit point of the piston rod from the cylinder. While pneumatic rod seals seal dynamically inwards towards the movable cylinder, they sit statically on the piston towards the outside.

Pneumatic rod seals are usually built as asymmetrical grooved rings with a shortened inner sealing lip. Therefore, the pressure load is only permissible from one side – rod seals are also referred to as single-acting seals.

Whether rod seals are installed with or without pre-compression depends on whether the seal is to be sealed only during operation of a machine or even at standstill. If a seal is not necessary in the pressure-free state, the pneumatic rod seal can be adjusted without pre-compression. The sealing is then carried out during operation by the system pressure pressing the grooved ring against the sealing surfaces.

If a continuous seal is required, rod seals must be installed with pre-compression by means of tension or pressure. This can then be released via a corresponding prestressing element such as a spring or an O-ring.

Piston seal

In pneumatic piston seals, a distinction is made between single-acting and double-acting piston seals. Single-acting piston seals are subjected to pressure from one side only, whereas double-acting piston seals experience pressure from both sides.

Single-acting pneumatic piston seals operate similarly to rod seals. The main difference is in the inversion of static and dynamic sealing functions. While the single-acting piston seal dynamically seals towards the outside, it remains statically positioned on the piston's interior. Therefore, this seal type, akin to the rod seal, is implemented as an asymmetrical groove ring with a shortened outer seal lip.

Double-acting pneumatic piston seals are designed to withstand pressure from both directions. They are applied where it's necessary to separate two chambers that might alternatively be under overpressure. Double-acting piston seals are typically symmetrical groove rings or compact rings in design.

Depending on the application, piston seals can also be installed with pre-compression, meaning they are fitted under pressure or tension.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Grooved ring seal

The ring-shaped groove rings feature an elongated indentation, known as a groove. This groove delineates the boundary between the two seal lips, which are each tasked with either dynamic or static sealing. Depending on whether it is an inner-sealing rod seal or an outer-sealing piston seal, the inner or outer lip is accordingly reduced in size. The configuration of the seal lip is crucial for the seal’s efficiency.

Typically, groove ring seals are composed of wear-resistant polyurethane (PU), low-friction, temperature, and chemically resistant polytetrafluoroethylene (PTFE) or a flexible and robust elastomer (elastic but deformable plastics that resume their original shape after stress), such as nitrile butadiene rubber (NBR).

For pneumatic applications in particular, utilizing self-lubricating materials with a MOS² compound proves beneficial. We offer both a PU-MOS² in various blends and PTFE MMOS².

Unlike compact rings, the space between the seal edges in groove rings is not filled with elastomer.

Scraper

Behind the pneumatic seal are the wipers. These components, barely exposed to pressure, serve two purposes. Firstly, they remove contaminants from the retracting piston rod, thus maintaining the system's cleanliness; secondly, they allow a thin layer of oil on the rod to lubricate the seal. Suitable wipers include sealing rings with rubber lips or special dual wipers that feature two sealing edges.

The inner sealing edge leaves a lubricating film upon extension, while it removes external dirt and other foreign objects from the retracting rod. Considering the temperature range and system pressure, materials for wipers can be PU (Polyurethane), PTFE (Polytetrafluoroethylene), or a flexible and robust elastomer such as Acrylonitrile Butadiene Rubber, also known as NBR (Nitrile Butadiene Rubber)

What are the requirements for pneumatic seals?

The use of various pneumatic systems in industry also requires individual solutions in the field of sealing technology. Each seal must meet a variety of requirements.

We will be happy to advise you on choosing the sealing solution that is right for you. With regard to areas of application and systems, we pay attention to the following core factors:

- Mechanical load

- Resistance to high and low temperatures

- Resistance to high pressure

What materials are used for pneumatic seals?

Depending on the requirements placed on the sealing elements, we use different materials (sealing materials) for the sealing of pneumatic systems in industry. The different material properties determine the selection of the right sealing elements in the pneumatics. Hardness, elasticity, chemical resistance, operating temperature or electrical insulation properties, for example, play an essential role.

Here is a compact data sheet with the most common materials:

| NBR | nitrile butadiene rubber or acrylonitrile butadiene rubber | -60 to 135°C (-76°F to 275°F) | excellent mechanical properties |

| HNBR | Hydrogenated acrylonitrile-butadiene rubber | -40 to 180°C (-40°F to 356°F) | particularly extensive application possibilities |

| EPDM or APTK | ethylene propylene diene monomer rubber Also Called Ethylene Propylene Terpolymer Rubber | -60 to 288 °C (-76°F to 550,4°F) | resistant, durable, chemical resistant |

| MVQ or VMQ | Silicone Rubber | -60 to 250°C (-75°F to 482°F) | Suitable for high temperatures |

Pneumatic sealing systems for demanding applications

Pneumatic sealing systems are employed wherever exceptionally high requirements for sealing efficacy and durability are demanded. In pneumatic installations subjected to extreme temperatures, aggressive chemicals, or severe contamination, a singular seal often proves insufficient.

Here, what's required are intricate sealing systems comprising several seals that complement each other. The sealing material is influenced by a diverse range of factors depending on the field of application, hence the importance of material choice.

To provide you with the best guidance possible, we are eager to offer our consultancy services. We tailor-make a sealing system specifically conceived for your application field, designed to meet your requirements. Our extensive assortment includes not just seals for pneumatic systems but also solutions for hydraulic installations and other sectors.

Also featured in our portfolio:

Special seals (including article numbers), replacement parts, support rings, thread seals, shaft seals (rotational seals, Simmerrings), molded parts, and flat seals. Browse our online shop, place your favorites in the cart, and order with ease.

Should you have any inquiries regarding sealing solutions and products, including datasheets, or questions about delivery times, shipping costs, or payment options, please don't hesitate to contact us via our hotline or pose your questions conveniently in our Kofler - Dichtungen chat