O-ring - What exactly are O-rings?

O-rings are proven, cost-effective seals for everyday applications and are installed in almost every hydraulic system. Normally, they are used statically at pressures of up to 130 bar (1885 PSI). If the pressure increases, one or two back-up rings may be added. The same applies to slightly larger sealing gaps, where a back-up ring may also be required.

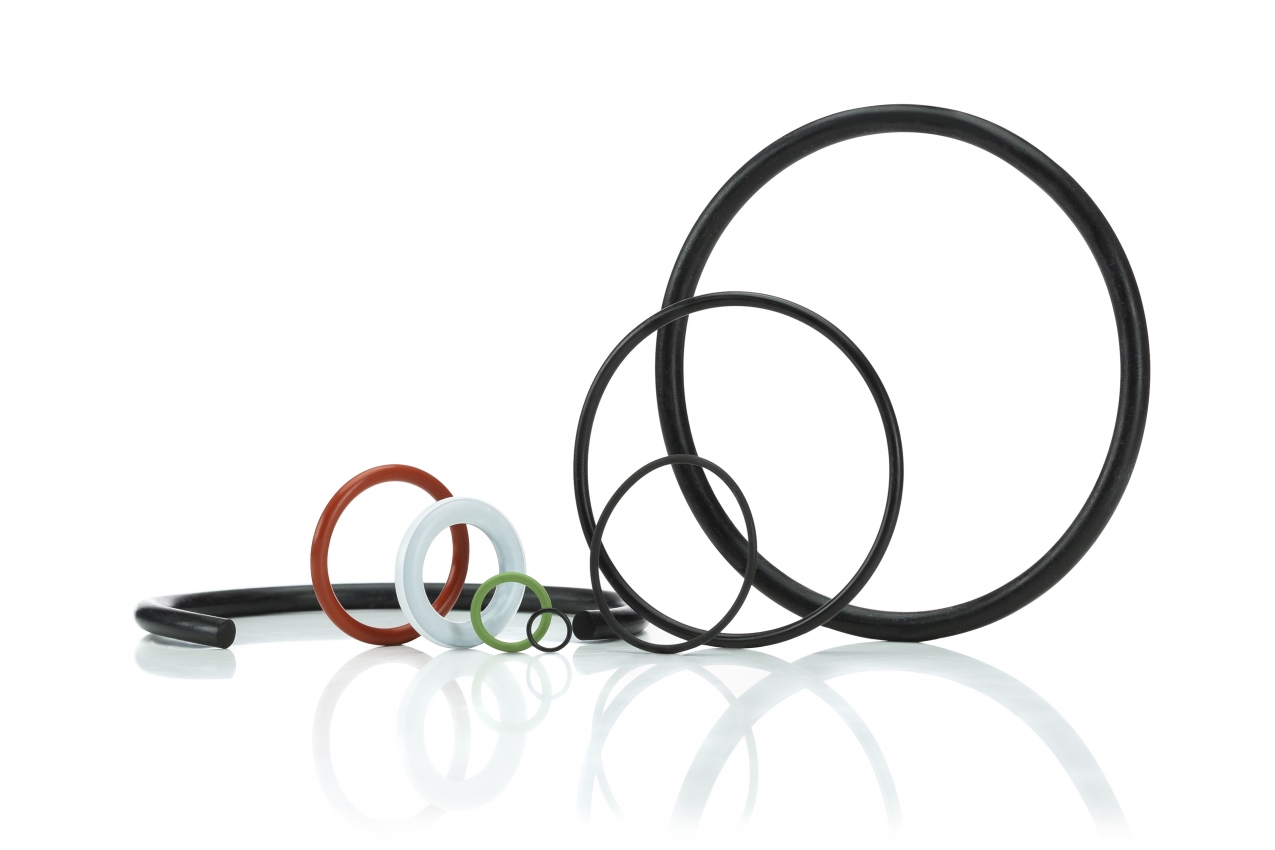

O-rings are manufactured from all common sealing materials to meet different requirements and needs. These materials include:

These industrial elastomers, with their elastic properties, provide optimal conditions for O-ring seals. For detailed qualities of these properties, please refer to this article. Such O-ring seals prevent the escape of liquid or gaseous media through the groove.

Often, it is necessary to install thick-walled sealing elements in closed spaces, making the installation of O-rings challenging and requiring expertise.

The media exert a constant pressure on the O-rings, necessitating high-quality O-rings. The manufacturing of O-rings follows strict tolerances, and the materials used are selected based on the application.

Do you have any questions?

How does an O-ring seal work?

But how exactly does an O-ring seal function in detail? The technical explanation is as follows: O-rings for industrial applications are designed to withstand a wide range of pressures and extremely high temperatures, thanks to the selection of the appropriate material.

The sealing effect is achieved through compact axial or radial compression.

The polar pressure acts as a friction force between the O-ring and the section holding it in place. By increasing the applied pressure, a barrier force is created between the O-ring and the opposing surfaces.

O-Rings for Industry - What types of O-Rings are available?

Depending on the application area, such as being part of a hydraulic seal or based on individual requirements, there are different designs for O-rings. Typically, sizes are differentiated, with measurements either in metric units or according to the American AS standard. In addition to the inner and outer diameters, the cord thickness of the respective rings is also a critical parameter. While the core of an O-ring is always elastic, it can be supplied with or without an encasement. Seamless encasements are typically made of PTFE or FEP. FEP is recognized under FDA regulation 21 CFR177.1550 as a material suitable for parts that come into contact with food. Shock-vulcanized O-rings, however, are produced from extruded (pressed) precision round cords. They are especially useful when large or specific dimensions are needed in small to medium quantities. It is important to note that these O-rings have limited pressure resistance. In our online shop, you can conveniently purchase O-rings and explore a wide range of common O-rings available.

O-ring materials - these elastomers are available for hydraulic seals

As already mentioned, O-rings are offered in different materials. The quality of the materials used is always important. An inferior base material ultimately affects the quality of the final product and your hydraulic seal is less efficient.

The following elastomers (rigid but elastically deformable plastics, rubber) are most commonly used to manufacture O-rings:

- Nitrile Rubber (NBR)

- Ethylene Propylene Rubber (EPDM)

- Fluorocarbon (FPM/FKM)

- Neoprene

- Polyurethane (PU)

- Silicone Elastomer (MVQ)

- PTFE

How do I find the right O-ring seal?

O-rings are not just utilized in the industrial sector. In everyday life, we constantly come across O-ring seals without even realizing it. Everything from industrial manufacturing devices to coffee machines and water faucets are equipped with O-rings for seamless operation. O-rings are also a component in watch manufacturing. Speaking of wristwatches, these typically use the smallest form of O-rings, measuring 0.7 x 0.2 mm (0,027 in x 0,0078 in).

In terms of sealing functionality, the primary purpose of O-rings is to prevent the escape of gases, oil, air, water, and other media. It is irrelevant whether the applications and devices are industrial or commercial. To find the appropriate seal for the specific need, the following aspects should be considered:

- Application

- Flange connections

- Sealing material

- Chemical resistance of the material

- Design

It is advisable to use performance testing to ensure you have selected the O-ring seals suited for your requirements. Besides the standard profiles, there's also the option for custom productions. Whether for rod seals, piston seals, or pneumatic seals as well as hydraulic seals, Kofler - Dichtungen is your trusted partner! We also provide flat gaskets, shaft seals, and Simmering seals.

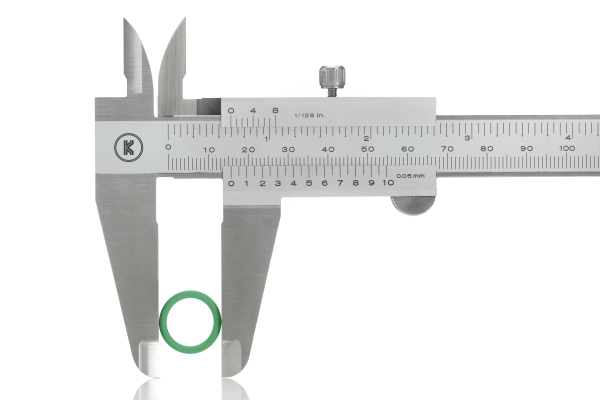

Specifications of O-ring seals

Depending on the specific application area and conditions, different types of O-ring seals are necessary. It's crucial to consider various specifications that aid in selecting the appropriate product made from suitable material for the intended purpose. The key factors in choosing O-rings include:

- Inner Diameter

- Cord Thickness (Cross-Section Diameter)

- Material Composition and Properties

- Material Hardness

Only by predefining these specifications and evaluating the O-ring seals accordingly, can you be assured of finding the right product. Our experts are always available to assist with any questions you might have.

If you're uncertain about which O-ring seal is the correct choice, we will help you locate the suitable product from our inventory. We ensure quick delivery of O-rings in Austria and Germany, allowing you to proceed with your project on schedule.

Custom O-Ring Manufacturing

Since 1988, Kofler Dichtungen has been supplying industrial and construction companies as well as mechanical engineering companies in Austria and Germany with high-quality seals. While initially mainly companies in Tyrol were supplied, today companies all over the world are among the customers of Kofler Dichtungen. The passion of company founder Gernot Kofler has always been "small parts with a big effect" - and this can be seen in the O-ring range for hydraulics and other applications.

In addition to an extensive stock of high-quality standard seals, the O-Rings catalogue also includes custom-made and high-tech seals for the highest demands. All seals are manufactured using the latest CNC techniques from high-quality and innovative materials. These include O-rings made of silicone (VMQ), polyurethanes, NBR, HNBR, Viton, FVMQ, EPDM, PTFE pure and filled (compound) as well as Viton, PU and EPDM with FDA certification. Of course, special materials such as Kalrez, peek or Aflas are also available on request.

The company was converted into a GmbH on its 30th anniversary in 2018 and since 2019 the two sons Fabian and Florian have been represented on the management board. Like their father, they attach great importance to competence, quality and trustworthiness in order to continue to satisfy existing and new customers and to supply them with high-quality seals for a wide variety of applications. Any sealing solutions are possible. O-ring sets are also often seals supplied by us!

If there is an article number or a data sheet for your O-ring seal, you provide us with this data so that we can optimize possible production times and delivery times for you.

Where are O-rings used?

O-rings can be found in a variety of applications. The O-ring, or sealing ring, is indispensable in sealing technology. O-rings are especially used in dynamic applications such as hydraulics or pneumatics.

What should be considered when buying O-rings?

In addition to dimensions such as the diameter, the thickness of the O-ring (cord diameter), the ideal material is the key to a long service life of the O-ring.

It is important to know here whether the O-ring has a high Shore hardness (Shore A, Shore B, Shore C, Shore D) corresponding to an increasing degree of hardness. What temperature range is the O-ring exposed to? Furthermore, where the O-ring is used, i.e. whether mechanical abrasion is an issue or to which media the seal is exposed. Does the O-ring seal gases, fuels, oils or other media.

Is there a difference between an O-ring and a backup ring?

Yes, there is a difference between an O-ring and backup rings. An O-ring is an annular sealing element made of rubber or plastic that is placed in a groove. It has a round cross-sectional shape and is used to create a static or dynamic seal between two or more components.

A backup ring, on the other hand, is a component that is normally used in combination with an O-ring. It is a flat or semi-flat ring used to hold and stabilize the O-ring in position. The backup ring can be made of different materials such as metal or plastic and is often used to improve the performance of O-rings by increasing pressure distribution and stability.

What is the difference between an O-ring and a shaft seal?

An O-ring and a shaft seal differ in their function and application. An O-ring is an annular sealing member that is mounted in a groove and is used to provide a static or dynamic seal between two or more components.

A shaft seal, on the other hand, is used to seal a shaft in a housing. It is inserted into a groove on the housing and has a lip that rests on the shaft to prevent leakage of lubricants or other liquids. The shaft seal can be made of various materials (FKM, EPDM, Viton, NBR, FFKM, acrylonitrile, butadiene rubber, NBR 70) and is often used in engines, transmissions, pneumatics, hydraulics and other rotating machine parts.

Overall, it can be said that the O-ring is a generally inserted seal, while the shaft seal is specifically designed for rotating applications to ensure a seal between the shaft and the housing. Shaft seals are often exposed to axial as well as radial forces or both at the same time.