-

Homepage

-

Seals and Gaskets

-

Flat gasket

- Graphite seals and gaskets

Graphite - Resistance and areas of application for graphite seals

Graphite as a material for seals forms the best basic properties for optimal sealing performance. Graphite as carbon can be used at - 240° to + 550° (-400°F to +1022°F), as well as with large temperature fluctuations. Due to this high temperature resistance, good thermal conductivity and generally good resistance, graphite seals are used in the following areas:

- Wherever gas is used; gas seals

- Carburetors

- Boiler seals

- Plant and equipment construction

- Welding technology

- Food industry, ovens (Wiesheu)

- Furnaces, at high temperatures

- Ventilation and air conditioning technology

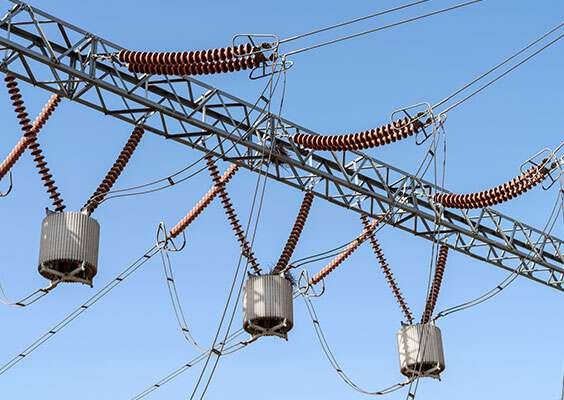

- Power Plants (GE Power)

A graphite seal has to meet some requirements. Depending on the specific area of application, the demand for a graphite flat gasket according to DIN 2690 varies:

- Heat stability

- Compressive strength

- Resistance to (hot)water and steam

- Resistance to chemicals (acids, alkalis) and solvents

- FDA approval of the material (e.g. in the manufacture of drugs)

The great advantage of graphite seals is that they are resistant to a variety of media and have a wide temperature resistance.

Special care must be taken when installing seals made of graphite. The sealing surface must not be scratched or kinked. If the material detaches from the metal insert, the gasket can no longer be mounted.

An alternative to graphite seals are PTFE - Teflon flat seals. These are also universally applicable, as the material Teflon (PTFE) is compatible with virtually all materials.

Order graphite seals for high temperatures

As a high-temperature seal, the graphite seal withstands extreme heat as well as cold. Graphite, the material used, provides the best attributes for temperature resistance, including during fluctuations in temperature. The tensile, compressive, and flexural strength of graphite even increases as temperatures rise.

Depending on the specific application of the seal, you may order a standard graphite seals or a custom-made flat gasket from graphite - available in any shape, size, and quantity. The longstanding expertise and experience of Kofler - Dichtungen ensures the highest manufacturing quality. This, in turn, guarantees high process and operational reliability.

The Kofler - Dichtungen portfolio, also offers the Novamica® Thermex seal. It offers a wide range of uses in high-temperature environments, such as in the metal industry for blast furnaces or as boiler gaskets.

Novamica® Thermex

The sealing material Novamica® Thermex is a seal made of phlogopite mica. As a flat gasket, it is suitable for the highest temperatures, chemical resistance and electrical insulation. Novamica® Thermex offers sealing up to +1,000°C (+1832°F), even in corrosive and aggressive media. It is mostly used in mechanical engineering, in the process industry, in the energy sector, in the glass industry, in furnace construction as well as in the automotive industry. The material is particularly suitable for seals in hot gas applications, exhaust gas applications or in blast furnaces.

The high-temperature material based on phlogopite mica has excellent material properties. Mica is a mined mineral used in electrical engineering. The material can be used optimally in particularly stressed areas such as high voltage and high temperature. Phlogopite mica is superior to other mica types due to its temperature resistance of up to 1,000°C (+1832°F).

Other benefits include:

- high chemical resistance

- good thermal and electrical insulation properties

- is non-flammable

- good adaptability to flange unevenness

- long stability

Graphite seals for high pressure

Graphite seals are particularly required in high-pressure processes. For example, in a metal press or steel press, a stable and high-pressure-resistant seal is essential. Graphite seals, such as SIGRAFLEX®, are suitable up to an operating pressure of 250 bar (3625,94 PSI) and are often used in apparatus construction due to this mechanical load capacity.

Kofler - Dichtungen offers the SIGRAFLEX® seal with special high-pressure technology. The experts at Kofler - Dichtungen produce special shapes and geometries for each different requirement.

SIGRAFLEX® High-Pressure Seal

The SIGRAFLEX® high-pressure seal plate is rated for up to 250 bar (3625,94 PSI). What sets this high-pressure graphite seal apart is its high-strength composite of graphite and stainless steel foils, which is entirely free from adhesives and binders.

This composite comes to life through SIGRAFLEX® HIGH PRESSURE technology, making the SIGRAFLEX® gasket both reliable and secure. Manufactured from flexible graphite, the gasket's surface is soft, affording it remarkable adaptability. It is treated with an impregnation to diminish leakage, achieving exceptional technical tightness even under low compressive forces.

This impregnation process also renders the material scratch-resistant, enhancing fault tolerance during installation and operation. SIGRAFLEX® is noted for its long-term stability in compression and resilience, even when subjected to temperature fluctuations. SIGRAFLEX® frequently finds applications in challenging and mechanically demanding sealing connections, such as tongue-and-groove flanges, apparatuses, heat exchangers, or custom seals.

Moreover, this graphite gasket is excellently suited for use with corrosive substances, steam conduits, boilers, thermal oil and heating systems, sight glasses, pumps, as an O-ring in valves or in legacy systems. Notably, it has also been successfully used as a sealant in systems involving liquid oxygen.

Graphite seals at low temperatures

Graphite seals are excellent at both high and low temperatures. Thanks to the special structure of graphite seals, they can also be used at very low temperatures down to minus 240°C (-400°F).

Other sealing materials, on the other hand, can become brittle, especially at low temperatures. This can negatively affect the tightness.

If you have any questions about resistance to temperature or high pressure, the expert team at Kofler - Dichtungen will be happy to assist you.

Graphite gaskets for flanges

Due to their high flexibility, graphite seals and gaskets are also ideally suited for use with flanges. A flange is an annular disk with which pipelines are connected to each other.

The graphite seal allows good adaptability to unevenness and roughness of the flange. Graphite seals can only be used once. Normal graphite seals are usually difficult to remove from the flange.

Sealing materials in combination with graphite

Depending on the requirements, sealing materials can be used in combination with graphite. For example, a graphite gasket can be used with glued stainless steel sheet inserts as well as with adhesive-free stainless steel foils.

Order Mica Seals and Gasket Plates Online

Products by Kofler - Dichtungen, such as a mica seal or mica gasket plate, can be ordered easily and conveniently online. In the online shop you will find a huge selection of standard products as well as special seals that can be individually adapted to your requirements.

Mica is a mined mineral used in electrical engineering. The material can be used optimally in particularly stressed areas such as high voltage and high temperature.

Buy flat gasket made of graphite with spit sheet insert

A flat gasket made of graphite can be reinforced with a spiked sheet metal insert, i.e. a steel insert. The bonding of graphite to the spear plate takes place mechanically and is therefore free of adhesives.

This gasket with metal insert is particularly suitable where steam is used. The combination with stainless steel makes the seal particularly temperature-resistant and can be used under alternating thermal and mechanical loads.

Graphite seal, custom-made and manufactured

A graphite seal can be ordered as a standard product as well as a custom-made seal from Kofler - Dichtungen.

As experts in the sealing sector, the family business Kofler can look back on over 30 years of experience. Great attention is paid to the needs of customers. Together with the customers, the ideal seal is developed and manufactured by Kofler - Dichtungen itself.

Custom-made seals are specifically tailored to the area of application. This allows for ideal use, longer durability and less leakage.

Leakage is the leakage of liquids and media such as gas. Seals should prevent leakage as much as possible. However, since no sealing material and no flange connection is 100% tight, leaks occur. The goal is to reduce leakage to a minimum by making the seal in the best possible way for the application. Pressure, temperature and aggressiveness of the media are the most decisive factors for customisation.

Depending on the material, various techniques are used in the production of flat seals, including a graphite seal. The sealing material in the form of a plate is cut to size, for example, using waterjet cutting technology, plotter technology or punching. Graphite seals are difficult to cut with water jet cutting technology.

Kofler - Dichtungen also offers absolutely competitive prices for custom-made seals and gaskets - through a targeted selection of the ideal manufacturing process. From small editions with water jets to series production of stamped flat gaskets, we will be happy to make you an individual offer. We stand for uncomplicated and fast processing of your orders.