-

Homepage

-

Sealing knowledge

- PTFE Seals and Gaskets - What is Teflon (Polytetrafluoroethylene)?

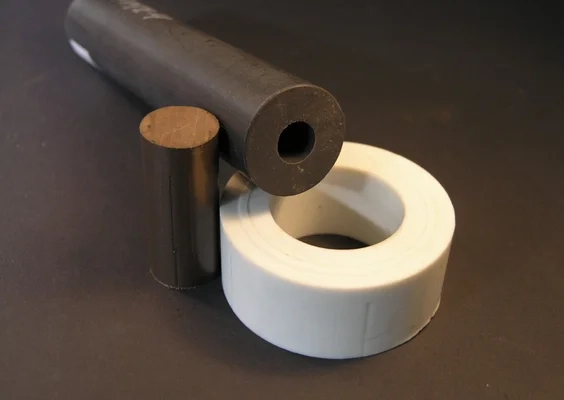

PTFE Seals and Teflon Gaskets by Kofler - Dichtungen

Discover the key properties, advantages, and industrial applications of PTFE – also known by the brand name Teflon®. As sealing experts, we at Kofler – Dichtungen provide you with comprehensive insights into this high-performance fluoropolymer: from its unique physical and chemical characteristics to its uses in demanding environments such as food production, medical technology, and chemical processing. Learn everything you need to know about PTFE seals and gaskets directly from the specialists.

What is Teflon (Polytetrafluoroethylene)?

What exactly are PTFE seals (commercially known as Teflon)? We, at Kofler – Dichtungen, aim to address this question in this article and further familiarize you with the characteristics and applications of polytetrafluoroethylene (PTFE).

Teflon is a trademark of the American company DuPont for the plastic polytetrafluoroethylene (PTFE), a synthetic fluoropolymer composed of fluorine and carbon. It was discovered in 1938 by Roy Plunkett, a chemist working for Chemours (then part of DuPont), during experiments involving refrigerants.

The bonds between fluorine and carbon in PTFE are chemically extremely stable, and therefore inert. Moreover, the high content of fluorine atoms bestows the material with a surface that is both water and oil-repellent, exhibiting very low friction.

These attributes lead to exceptional properties that find utility in numerous applications. The most well-known uses include non-stick coatings for kitchenware such as pots and Teflon-coated pans, and also GoreTex membranes (thin, breathable PTFE films).

Teflon also sees widespread use in industry and in seals, particularly when there's a demand for the highest resistance to chemicals or excellent sliding characteristics, making use of comprehensive seal sets. The subsequent sections will discuss further advantages of using poly tetrafluoroethylene over other plastics. Learn about our sealing knowledge.

PTFE Seals and Gasket - What are the characteristics of Teflon ?

PTFE (Teflon) is a modern high-performance plastic and the most important fluoropolymer. Its unique features include an extreme operating temperature range, resistance to highly aggressive chemicals, low friction (sliding friction), and non-stick properties as a sealing material. Like POM and PEEK, PTFE is classified among thermoplastics, meaning it becomes moldable upon heating. A newer development is the rubber-elastic fluorocarbons FPM (FKM, brand name Viton) and FFKM (brand name Kalrez). They combine the elasticity of synthetic rubber, like EPDM, with the chemical stability and resistance of PTFE.

Teflon - Physical properties

Teflon is an excellent electrical insulator with high dielectric strength and a low dielectric constant, making it ideal for high-frequency applications in electronics and aerospace. The surface tension is extremely low and therefore it is very difficult to wet, so that it is both water-repellent and grease-repellent. Similar to the MVQ/VMQ silicones, PTFE has a high gas permeability. That is why PTFE and ePTFE are very suitable for use in the food industry.

PTFE and its mechanical properties

PTFE exhibits good impact resistance, yet it is relatively soft, not very stiff, and exhibits low hardness (Shore D 50-72). Teflon boasts exceptional sliding properties: the friction coefficient is very low, making it ideal for dynamic sealing and guiding elements. This low coefficient of friction reduces energy loss and wear, especially in industrial applications where consistent performance at low temperatures is critical.

Notably, the static friction coefficient and the dynamic friction coefficient are the same, meaning the transition from rest to motion happens smoothly, without jerking. The surface of PTFE is anti-adhesive, preventing it from bonding with sticky substances. For this reason, it is also commonly used as a dry lubricant in applications where conventional greases or oils are unsuitable.

The primary weakness of Teflon lies in its relatively low wear resistance; it cannot match the high durability of materials such as NBR or HPU solid, which demonstrate superior wear resistance. This limitation can be significantly mitigated by incorporating fillers like graphite or bronze into composite materials known as compounds. Moreover, Teflon is prone to creeping under constant stress

PTFE - Thermal properties

PTFE is extremely thermally stable and retains its mechanical properties in the temperature range from -200°C (-328°F) to high temperatures of +260°C (+500°F). At higher temperatures and in fires, PTFE decomposes into toxic and corrosive gases.

Teflon has an extremely high resistance to almost all chemicals. Even concentrated acids, alkalis, alkalis, alcohols, fuels, solvents, oxidants and ozone cannot harm PTFE. It is very weather resistant. Only the most extreme corrosive substances such as fluorine gas and molten alkali metals attack it.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

PTFE - Biocompatible

Due to its high chemical stability, PTFE is regarded as biocompatible and deemed physiologically safe. It is available in grades with FDA approval for use in the food industry and medical technology. Polytetrafluoroethylene can be blended with organic and inorganic materials, such as glass fibers or graphite, leading to new product characteristics differentiated by hardness, abrasion resistance, and compressive strength. PTFE also shields rollers and pistons against corrosion.

When polytetrafluoroethylene is combined with organic or inorganic substances like graphite, glass fibers, or metal powder, it can further enhance product attributes, including hardness, abrasion resistance, or compressive strength.

PTFE in medical technology

In medical technology, PTFE is widely used due to its biocompatibility and inert nature. One notable application is in the manufacturing of catheters, where its low surface energy and low coefficient of friction help reduce tissue irritation and improve insertion comfort. The material’s dielectric strength and chemical resistance further contribute to its reliability in sensitive environments.

Buying a PTFE Gasket or Seal - What Are the Benefits of Teflon?

PTFE is an extremely versatile material for sealing technologies and can be employed in nearly all sealing applications. It is suitable for a wide range of temperatures, from very low to very high, with PTFE flat gaskets operating at temperatures from -200°C (-328°F) to +260°C (500°F), maintaining stability across virtually the entire pH spectrum.

It remains indestructible even when exposed to most of the harshest chemicals and is non-flammable. PTFE is resistant to oxidants and UV radiation and does not age, weather, or corrode.

The only drawback is its tendency to flow and creep under stress, which may necessitate regular maintenance.

PTFE seals - Where are Teflon gaskets used?

PTFE seals are always used when good sliding properties, wide temperature ranges and high chemical resistance are required. The low friction makes Teflon the ideal material for various industries when dynamic seals are required (e.g. as a hydraulic seal and pneumatic seal). What exactly are hydraulic seals?

PTFE is also used for mechanically demanding dynamic seals: as a rod seal, scraper or piston seal. Mechanical strength is improved in such cases by fillers, e.g. PTFE compounds such as PTFE bronze, PTFE carbon and PTFE moss².

Corrosive chemicals are processed as standard in the chemical and pharmaceutical industries. Seals made of PTFE are omnipresent here, because ordinary rubber seals and seals made of silicone would be attacked and show inadequate service life. PTFE seals are also often used in fittings and valves, such as turbine construction and hydroelectric power plants.

Teflon seals are used in food production because it is naturally stable to acidic media (e.g. beverage production) and it is approved for use in food production. In addition, the thermal conductivity can be greatly improved.

Order PTFE Seals and Special Gaskets online directly from the Seal Manufacturer

As a seal manufacturer, you can easily order PTFE seals and special gaskets online from us. Kofler - Dichtungen supplies you with seals made of PTFE according to your requirements. We supply you with standard PTFE seals and special seals. We carry flat gaskets, O-rings, moulded parts, semifinished products and standard profiles in many sizes from 4 mm (0.15 inch) to 2,500 mm (98 inch) inner diameter. Our PTFE flat gaskets for flanges (flange gaskets) are shipped in different versions and as a special gasket with article number.

To meet the most demanding needs, we also offer customised industrial seals made of PTFE and PTFE compounds: get in touch with our sealing experts. We are happy to hold a consultation with you so that you can receive a custom-made Teflon seal.

We will also be happy to send you our data sheet and seal pallet. In addition to PTFE, we also offer other elastomers (Viton, HPU, etc.) as well as flat seals made of stainless steel. Registered companies can order online in our online shop without VAT. Send us your request via our contact form. You will receive the products from your shopping cart with a short delivery time and will be able to book a positive shopping experience through good advice, fair shipping costs and fast processing of your order. We offer a wide range of seals, including standard profiles such as the Simmerring seal.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."