-

Homepage

-

Seals and Gaskets

- Hydraulic seals

Hydraulic Seals from Kofler - Dichtungen

Kofler - Dichtung is your expert manufacturer and supplier when it comes to high quality hydraulic seals and gaskets. These seals must be able to withstand high pressure, dynamic movements and different operating conditions without losing their sealing properties. Efficient hydraulic seals are indispensable to prevent leaks that waste operating fluids, endanger the environment and occupational safety. They also prevent efficiency losses, increasing energy consumption and expensive repairs.

Kofler - Dichtungen is aware of these special requirements and offers an extensive range of hydraulic seals that have been specially developed for the diverse fields of application in industry. These products are characterized by their high quality and durability; they are available in a variety of materials and designs to ensure optimal compatibility with the operating fluids and operating conditions. From NBR to FKM (FPM) to specialized materials such as PTFE and HPU, we offer solutions tailored to the specific requirements of your application.

Request your hydraulic seal

Areas of application for Hydraulic Seals

Hydraulic seals are indispensable components of numerous machines and systems that use hydraulic systems to transmit movement and force. These seals ensure the tightness and efficiency of hydraulic cylinders and systems by preventing the leakage of liquids, thus ensuring the performance and reliability of the systems.

The fields of application of hydraulic seals are diverse and extend across numerous industries where precision and reliability are required. Here is a list of the most important areas of application and industries:

- Mechanical and plant engineering

- Automotive

- Construction (for construction machinery such as excavators, cranes and bulldozers)

- Agriculture (for tractors, combine harvesters and other agricultural equipment)

- Mining and Tunneling

- Energy generation (for turbines in hydroelectric power plants)

- Heavy industry (for steel, cement and paper production)

- Aerospace

- Shipbuilding

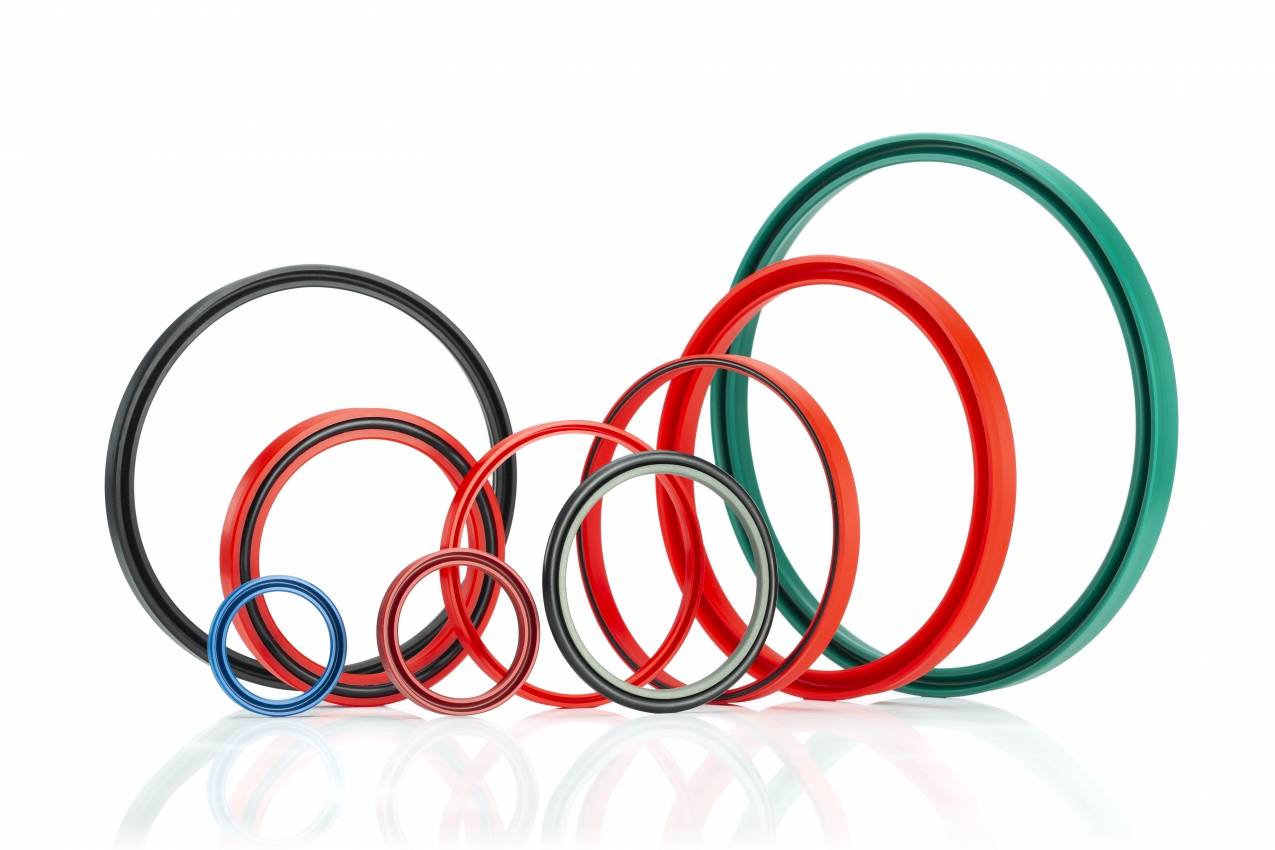

Different seals for hydraulic applications

Hydraulic systems are at the heart of many industrial applications and machines. They require precise and reliable sealing solutions to prevent leaks and ensure system efficiency.

Kofler - Dichtungen offers a wide range of hydraulic seals specially developed for these demanding requirements. Here is an overview of the different types of hydraulic seals that Kofler - Dichtungen offers:

Scraper for hydraulic seal

Scrapers protect the inside of a hydraulic cylinder: they remove dirt, moisture and other impurities that could adhere to the rod before it returns to the cylinder. This prevents damage to the internal seals and components and extends the life of the system.

Rod seal for hydraulic seal

Rod seals are designed to maintain pressure within the hydraulic cylinder and prevent leakage of fluid along the rod. They must withstand high pressure differences and are crucial for maintaining the efficiency and performance of the hydraulic system.

Piston Seals for Hydraulic Seals

Piston seals sit on the piston and seal the space between the piston and the cylinder wall. They allow the piston to move efficiently by holding the pressure on one side of the piston. This is essential for converting hydraulic energy into mechanical work.

Guide rings for hydraulic seal

Guide rings or guide bands are used to guide the piston and rod within the cylinder. They prevent direct contact between metallic components, reduce friction and wear, thus improving the service life and performance of the hydraulic system.

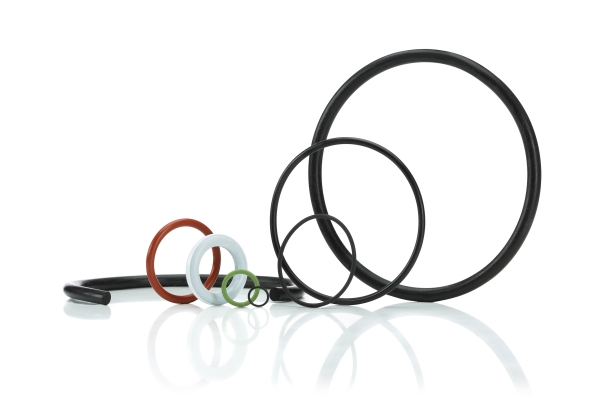

O-Rings for hydraulic sealing

O-rings are versatile sealing elements that can be used in a variety of hydraulic applications. They provide simple and effective static sealing of hydraulic fittings against liquids and gases and are available in different materials to withstand different operating conditions and temperatures.

Hydraulic sealing sets (complete sets of all components)

For comprehensive maintenance or repair, we offer complete sealing kits that contain all the necessary sealing components and spare parts for a specific hydraulic cylinder.

These sets are a handy solution to ensure you have all the parts you need at hand and ensure compatibility between seals. You will receive further seals such as shaft seal (sealing ring), support rings, flat seals, seals made of stainless steel, compact seals and much more.

Sealing materials for hydraulic applications – NBR, HPU, PTFE, FKM and more

Choosing the right sealing material is critical to the performance and reliability of hydraulic systems. Different applications require different properties of sealing materials, such as resistance to temperatures, chemicals, pressure and abrasion. Here are some of the most common materials for hydraulic seals and their characteristic properties:

NBR (Nitrile Butadiene Rubber)

NBR is one of the most commonly used materials for hydraulic seals – due to its excellent resistance to oils, lubricants and water.

It offers good mechanical strength and is resistant to abrasion, making it ideal for high-pressure applications. NBR works well in a temperature range of -30°C to +100°C (-22°F to 212°F), making it a versatile choice for many hydraulic systems.

PTFE (Polytetrafluoroethylene)

PTFE, also known under the brand name Teflon, is characterized by its exceptional chemical resistance and a wide temperature range from -200 °C to +250 °C (-328°F to +482°F).

It has a very low coefficient of friction, which minimizes wear and improves the efficiency of hydraulic systems. PTFE is ideal for applications where high chemical resistance or minimal friction is required.

HPU (Hydrolysis Resistant Polyurethane) for hydraulic seals

HPU (Hydrolysis Resistant Polyurethane) is an advanced material for hydraulic seals specially designed for its excellent resistance to hydrolysis, microbes and many chemicals. Compared to conventional polyurethane, HPU offers improved performance in humid or aqueous environments, as well as in applications where the seals regularly come into contact with water or other liquids.

This makes HPU an ideal choice for hydraulic seals in water management, marine applications and food processing where durability and reliability are required under demanding conditions.

In addition, HPU is characterized by its high abrasion resistance and its ability to provide excellent sealing performance even at high pressures and over a wide temperature range. The use of HPU material for hydraulic seals thus contributes significantly to increasing the efficiency and lengthening the maintenance intervals of hydraulic systems.

PTFE (Polytetrafluoroethylene)

PTFE, also known under the brand name Teflon, is characterized by its exceptional chemical resistance and a wide temperature range from -200 °C to +250 °C (-328°F to 482°F).

It has a very low coefficient of friction, which minimizes wear and improves the efficiency of hydraulic systems. PTFE is ideal for applications where high chemical resistance or minimal friction is required.

FKM (Fluorocarbon Rubber)

FKM, often known by the trade name Viton, offers excellent heat, oil and chemical resistance.

It is particularly suitable for applications involving extreme temperatures from -20°C to +200°C (-4°F to +392°F) and aggressive chemicals. FKM seals are ideal for use in the chemical, automotive and aerospace industries.

Other materials you can order for the hydraulic seal

In addition to NBR, PTFE, and FKM, there are a multitude of other materials that can be employed for specific requirements in hydraulic systems. These include Polyurethane (PU), known for its significant abrasion resistance and elasticity, EPDM (Ethylene Propylene Diene Monomer), recognized for its resistance to weather, ozone, and steam. Furthermore, specialized materials like Kalrez, Aflas, and PEEK have also been developed for use in exceptionally challenging applications.

Why hydraulic seals from Kofler - Dichtungen?

An effective hydraulic seal is a fundamental element in numerous machines and systems. Deficiencies can lead to leaks, posing significant dangers to people and the environment. Moreover, leaking seals can impair system efficiency, increase energy consumption, and ultimately lead to expensive downtimes and repairs.

At Kofler - Dichtungen, you benefit not only from our extensive product range but also from our decades of experience and technical expertise in the sealing industry. We are eager to assist you in choosing the appropriate seals for your hydraulic systems, ensuring maximum performance and reliability.

Each application is unique. Therefore, in addition to a broad selection of standard seals for hydraulic and pneumatic systems, we also provide customized solutions and sealing elements. Whether you need rod seals, grooved rings, piston seals, or scrapers, you will find the precise seal for your specific requirements with us.

We invite you to send us the measurements and sketches of the seal you require (outer diameter, inner diameter, metric specifications), and our seal experts will identify an appropriate solution for you.

Our aim is not just to supply products, but to offer solutions that enhance the efficiency of your facilities while also reducing operating costs.

Consequently, our experts in sealing technology are always at your disposal to address your queries and offer support.

FAQs about Hydraulic Seals

How to Seal a Hydraulic Cylinder?

To seal a hydraulic cylinder, it is essential to install the correct seals and sealing elements in the appropriate locations. Follow these steps for effective sealing:

Disassembly: Carefully dismantle the hydraulic cylinder to access the seals. Keep all parts clean and organized.

Cleaning: Clean all parts thoroughly to remove any dirt and debris. It is crucial that the sealing surfaces are free from damage and contaminants.

Inspection: Check all components for wear or damage, with special attention to the piston rod and cylinder tube surfaces.

Replacement of Seals: Remove old seals and replace them with new ones, ensuring the correct types and sizes are used.

Assembly: Reassemble the cylinder, putting all parts back in the reverse order of disassembly. Ensure that all seals are correctly positioned and no components are damaged during assembly. For guidance on the proper installation of seals, visit our YouTube channel at Installing Seals.

Testing: Finally, test the cylinder for leaks and proper function to confirm that the repairs have been successful.

What is a Rod Seal?

A rod seal is a critical sealing element in a hydraulic cylinder, placed around the piston rod. Its primary function is to prevent hydraulic fluid leakage along the piston rod and to block contaminants from entering the cylinder.

Rod seals are vital for withstanding high pressure differences and crucial for the hydraulic system's efficiency and performance.

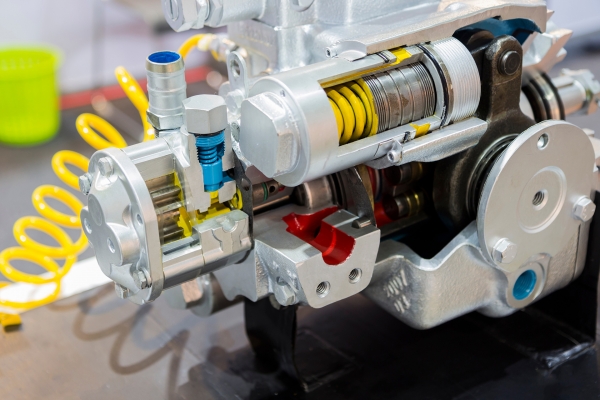

Structure of a Hydraulic Cylinder

A hydraulic cylinder comprises several key components:

Cylinder Tube: The housing that forms the pressure chamber.

Piston: Moves back and forth within the cylinder tube and transmits the force of the hydraulic fluid.

Piston Rod: Conveys the piston's movement and force externally.

End Caps: Seal the cylinder tube at both ends.

Seals: Maintain cylinder tightness, including rod seals, piston seals, and scrapers.

Guides: Stabilize the movements of the piston rod and piston. Together, these components convert hydraulic energy into mechanical work.

Applications for Hydraulic Seals

1. Mechanical and Plant Engineering: Hydraulic seals ensure smooth operation of hydraulic drives and control systems in industrial machinery and plants.

2. Automotive Industry: Employed in braking systems, steering mechanisms, and shock absorbers.

3. Construction: Vital for the functionality of machinery like excavators, cranes, and bulldozers to perform lifting and moving tasks.

4. Agriculture: Enable efficient operation of hydraulic systems in tractors, combine harvesters, and other farming equipment.

5. Mining and Tunneling: Enhance the safety and efficiency of machinery under extreme conditions.

6. Power Generation: Important in the maintenance and operation of turbines in hydroelectric plants.

7. Heavy Industry: Used in hydraulic presses and heavy machines for steel, cement, and paper production.

8. Aerospace: Control critical systems such as aircraft flaps and landing gear.

9. Shipbuilding: Special hydraulic seals are needed for reliable functioning of systems like rudder and anchor winches in saline sea water.