-

Homepage

-

Sealing knowledge

- VITON® Seals and Gasket - What is the material FKM, FPM

VITON® Seals and VITON® Gasket by Kofler - Dichtungen

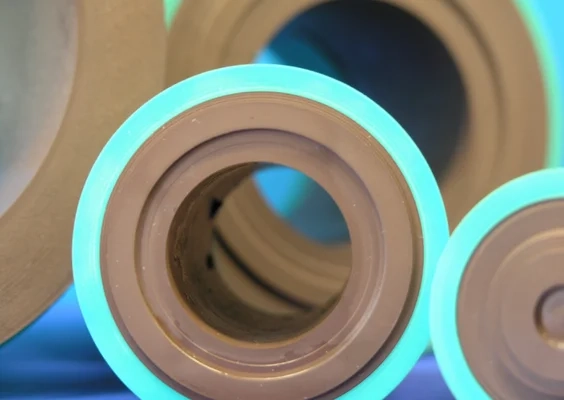

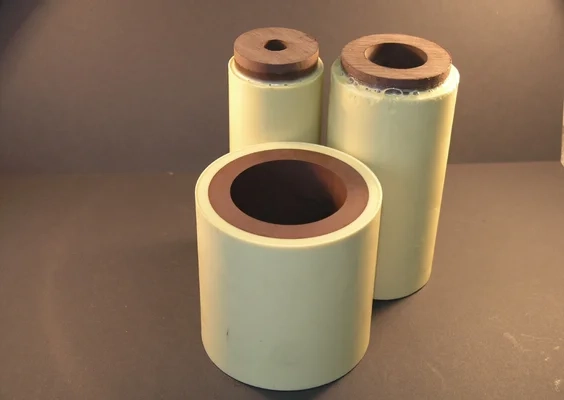

VITON® (FKM) stands for high-performance sealing solutions in environments with extreme temperatures, aggressive chemicals, and demanding mechanical stress.

As your sealing expert, Kofler – Dichtungen provides you with detailed insights into the properties, benefits, and typical uses of VITON® seals and gaskets.

Learn how this advanced fluoroelastomer ensures long-term durability and reliability in critical industrial applications.

You can order your VITON® (FKM) gaskets from Kofler - Dichtungen. Send us your request through our contact form!

Viton® Gaskets and Seals - Get in contact

VITON® knowledge - What is behind the material FKM, FPM

Viton Seal and Gasket - Viton® Fluoroelastomer has some different names. The terms FKM, FPM, Viton®, FKM Viton material in the field of fluorinated rubbers are perceived by many people as confusing. That is why we first clarify what we are talking about and what these terms mean:

- FKM: is the international ISO designation for all fluoroelastomers

- FPM: is the German DIN designation for fluoroelastomers

- Viton®: is a brand name for fluoroelastomers that was coined by the US company DuPont (similar to the term "Tempo" is also used colloquially for handkerchiefs from other manufacturers) The Chemours company is an American chemical company that was split off from DuPont (DuPont Performance Elastomers) in mid-2015

Read all about seals.

Viton® known as FKM and FPM

Viton® (FKM, FPM) is thus a broad term and generally refers to crosslinked polymers that contain fluorine. The backbone of the polymer can be constructed very differently depending on the monomer building blocks used in the production. Various formulations are developed to optimize specific properties such as chemical resistance, low-temperature flexibility, or compression set.

The basic building block is always VDF (vinylidene difluoride, 1,1-difluoroethene), to which other monomers are added in order to optimize the various parameters of the finished elastomer, for example HFP (hexafluoropropylene) and/or tetrafluoroethylene, which is also the basic building block for Teflon.

The ratio of the monomers to one another determines the various physical and chemical properties, for example, a higher proportion of tetrafluoroethylene leads to better chemical resistance, although reductions in the operating temperature and mechanical properties are to be expected. Viton's high resistance to aging is absolutely outstanding.

Basically, the terms FKM, FPM or Viton® always mean the same type of material: a fluorine-containing elastomer with very special properties.

You can order your Viton® seal and gasket from Kofler - Dichtungen online. As a customer, you can add your seal to the shopping cart and receive the prices plus shipping costs.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Viton® Seal - The Characteristics of an FKM Gasket or FPM Gasket

Viton® - Physical properties

The physical properties of Viton® are defined by its special chemical composition. The very stable fluorocarbon bonds result in a high flow resistance, which means that fluorine rubbers are good electrical insulators.

The polymer chains are in close interaction with each other, so that even gases can only migrate slowly through them: low gas permeability. In addition, FKM materials are very abrasion-resistant.

Depending on the application, FKM seals are available in various hardness levels, typically measured in Shore A durometer. Standard durometer ratings for FKM range between 60 and 90 Shore A, allowing precise adaptation to different sealing requirements.

FPM - Thermal Properties

The thermal properties of FPM make it an ideal material for applications at higher temperatures. It can withstand temperatures up to 200°C (392°F) without further ado. In the low temperature range, however, the material becomes brittle from about -20°C (-4°F), depending on the monomer mixing ratio and crosslinking method.

FKM - Mechanical properties

FKM has very advantageous mechanical properties. It is very resistant to tearing (elongation at break of 100% up to 300%) and shows only low impact elasticity. The compression set is very small, the sealing material deforms only slightly due to the action of pressure.

Viton® - Chemical resistance of FKM, FPM

Regarding chemical resistance, Viton® (FKM, FPM) possesses properties highly advantageous for demanding applications. The significant chemical stability of FKM results in exceptional resistance against a multitude of aggressive substances, including acids, bases, aliphatic and aromatic hydrocarbons, as well as halogenated compounds. FKM is also resistant to fats, vegetable oils, mineral oils, and silicone oils.

Crucially, it has a high fluid resistance and displays excellent resistance to fuels, which do not cause FKM to swell even under prolonged exposure. Furthermore, FKM is compatible with UV radiation and ozone.

Only steam, alcohols, and polar solvents adversely affect FKM.

Viton® Seals - What are the advantages of an FPM gasket or FKM gasket?

If you're considering a Viton® seal or gasket alongside other types of rubber for your sealing application and set, the following points should be taken into account:

Viton® and its compatibility gasket material

Viton® has great compatibility as gasket material.

- Viton® is compatible with diesel and gasoline

- Resistant to ozone, light, and weather conditions

- Resistant to acids and oils, compatible with many aggressive chemicals

- Heat-resistant

Viton® Versus Silicone

While both silicone and FKM (or Viton) are used across many applications, they exhibit different properties. Although silicone rubber and fluorocarbon rubber (FKM) share similar characteristics, the fluorine groups in FKM contribute to its distinct chemical resistance and compatibility.

This results in a significantly wider spectrum of applications for FKM when compared to silicone.

Viton® - Durability and Resistance

- Viton® is resistant to mechanical loads

- Low wear

- Low abrasion

- Excellent resistance to oxidation and aging

Viton® - Performance of FKM / FPM

- Viton® has good adhesion to metal

- Very low flammability

- Great performance in extreme conditions and high temperatures

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

What are the disadvantages of a Viton® seal

Incompatibility

There are a few substances with which FKM is not compatible: aggressive organic acids, polar organic liquids such as some solvents (ketones such as acetone, esters such as ethyl acetate) or amines

Performance

The performance of Viton® at high temperatures is very good, but in the case of extremely high temperatures and fires, FKM can release the gas hydrogen fluoride, which is not only corrosive, but also very toxic. Therefore, Viton® is not ideal at too high temperatures.

At low temperatures, FKM materials lose their elasticity and can break due to the embrittlement.

Viton® applications - Where are Fluoroelastomer (FKM) seals used?

The Viton® application areas are very versatile. Fluororubber (FKM) is a modern high-performance material and is therefore ideally suited for demanding high-tech applications. Both O-rings and hydraulic seals such as rod seals or scraper / wiper seals, flast gaskets, piston seals and special seals are manufactured from FKM. The Viton seal for a flange is also classic as a flange seal with prefabricated recesses (holes) for the screw connection. Often used in combination with stainless steel.

Examples of different application areas, sealing solutions and industries are:

Aerospace:

FKM has been specifically researched and developed for the extreme requirements in terms of temperature and chemical resistance in the aerospace industry.

Automotive industry:

Seals and hoses are often made of fluorinated rubbers, and Viton is also suitable for sealing technology in the area of brake fluid, as Viton provides high heat resistance in parallel - an often chosen area of application.

In addition to seals and hoses, FKM is also used for high-performance components such as diaphragms in fuel systems, where temperature and chemical resistance are essential.

Petroleum industry:

Viton® seals and O-rings made of FKM are omnipresent in the petroleum industry, from the refinery to the filling station, long-term fuel contact is to be expected, as there are outstanding properties compared to fuels, mineral oil and lubricants.

Chemical industry:

Due to the processing of aggressive chemicals in the heavy chemical and chemical processing industries, seals and hoses made of FKM, known for their high resistance, are in demand.

Furthermore, gloves made of FKM are an essential part of the personal protective equipment for employees.

Pharmaceutical industry:

As in the food industry, Viton® is very suitable for the pharmaceutical industry due to its technical properties for contact with drugs or the associated equipment.

Appropriate approval is also required here.

Food industry:

Since FPM is also available as a food-safe version, the material is often used for the food sector in the food industry.

Due to its excellent media and temperature resistance, FPM is well suited, for example, for filling systems for milk or fruit juices. Pay attention to the designation FPM/FDA.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Fluororubber compared to other elastomeric materials

Viton® and EPDM

EPDM (ethylene propylene diene monomer) is a synthetic rubber made from ethylene and propylene, offering excellent resistance to heat, ozone, and weathering. However, unlike Viton®, EPDM is not resistant to fuels and many oils.

Viton® and NBR

NBR (nitrile rubber) is also known as Buna-N. It has a similar resistance to mineral oils as Viton® and is therefore traded as a more cost-effective alternative.

Buna-N is significantly less resistant to weathering, UV, temperature and ozone.

Viton® and HNBR

HNBR is a special quality of NBR. It is significantly more weather, UV and ozone resistant and has a higher operating temperature than standard NBR. Although it does not reach the quality of Viton®, it is a cheaper alternative for some users.

See also our material PTFE (Teflon). Another plastic developed by DuPont.

Viton® standard seal and FKM custom-made special seal

With Kofler - Dichtungen, you get seals and gaskets made of FKM according to your requirements. We supply you with standard seals such as flat gaskets, standard seals and FKM O-rings, such as the O-ring FKM 75.

To meet the most demanding needs, we also offer you fluoroelastomer (material with increased fluorine content) industrial seals made to measure: get in touch with our sealing experts. You can have your custom seals made.

We are happy to hold a consultation with you so that you can receive a custom-made FKM seal. Standardized seals (ASTM) can be ordered easily and quickly in our online shop for companies. At Kofler - Dichtungen you can also buy hydraulic seals and order your required pneumatic seal.

Send us the article number or the data sheet of your FKM, FPM or Viton seal, so we can keep production and or delivery times short! We also offer Simmerring seals.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."