-

Homepage

- Seals and Gaskets

Sealing Solutions - Expertise from the Seal Manufacturer

As a seal manufacturer, Kofler - Dichtungen has extensive expertise in the field of sealing technology. The field of application is huge and therefore the question arises: What exactly are seals, what types of seals are there and how do they work? In the following article, we want to provide answers and explanations and also look at what a seal has to do to meet different requirements.

However, one thing should be said in advance: In order to ensure and maintain the desired function, seals must always be tailored to the respective applications and requirements. Defective seals have far-reaching effects: If, for example, the hydraulic seal of an excavator is defective, the entire device comes to a standstill because the bucket no longer works. If a faucet drips, its seal is defective. A leak can have more serious consequences, for example in filling systems in the pharmaceutical industry: If a seal is defective, then the entire production is at a standstill.

Therefore, quality and expertise in sealing technology are crucial for performance and longevity. Kofler - Dichtungen has been a specialist in sealing solutions for many years and offers customer-specific solutions and expertise for every requirement.

Sealing technology - What types of seals are there?

In sealing technology, seals are generally defined as elements or constructions designed to prevent or limit undesirable material transfers from one location to another. There are various types of seals tailored for different needs, among which contact seals constitute the largest category. These are employed both in static and dynamic applications. In dynamic settings, elements are categorized based on their motion in relation to each other, whether it be linear, as a stroke, or rotational

Buy Static Seal online:

Order dynamic seals in our online shop:

- Piston rings

- Stuffing boxes

- Sealing profiles

Non-contact seals, on the other hand, are primarily used on moving seal surfaces. They are deployed in dynamic applications where maintenance is challenging or when very high relative velocities occur. Such applications are predominantly found in the construction of gas, water, and steam turbines. In most instances (with the exception of magnetic fluid seals), the sealing here is not absolute, but only limiting, as there always remains a small free cross-sectional gap.

Non-contact seals:

- Mechanical seals

- Centrifugal discs

- Labyrinth or gap seals

- Sealing air

Contact Seals - Static and Dynamic Seals

Contact seals are employed in both static and dynamic applications. Static seals, as suggested by their name, are immobile and are tasked with sealing machine parts together that do not move relative to each other after assembly.

Dynamic seals, however, involve the individual sealing elements moving either translationally, meaning in a straight line, or rotationally, meaning in a circular motion, relative to each other.

Static Seal - Which seals are these?

Typical applications for static seals include the sealing of flanges, valves, plates, and closures. Their primary function is to seal immovable machine parts to each other. Depending on the application area and specific requirements, both custom and standardized dimensions are utilized, particularly in the fields of mechanical and plant engineering.

Static seals are available in a wide range of materials. Besides the O-ring, the most prevalent form of static seal, there are numerous other variants, including:

- X-ring

- Rectangular ring

- U-ring

- Flat gasket

Flat gaskets come in various shapes and sizes. Depending on customer specifications or the intended application area, they can be manufactured using different methods.

- Die-cut flat gaskets are especially well-suited for large-volume orders.

- Waterjet cut or CNC plotted flat gaskets are typically used for thicker materials, with series production possible.

Additionally, flat gaskets can be cut from tube stock or produced using injection molding and compression molding techniques. Various production methods are complemented by a diversity of materials or material combinations. For instance, rubber-metal composites are possible, wherein the elastomeric material is vulcanized onto a metallic substrate.

Other static seals include sleeve seals and profile seals, employed to block the entry of air and moisture. They find increasing use in thermal insulation and in industries where specific areas must be hermetically sealed.

Dynamic seal

Dynamic seals are required when the individual components, as well as the seals themselves, move relative to each other. They have the task of preventing or reducing mass transfer from one room to another to a permissible level. A distinction is made between different types of seals:

- Rotary seals: The sealing elements perform a circular movement with respect to each other. Depending on the type of pump, different rotary seals can be used. Rotary seals are also known as shaft seals.

- Translational seals: The sealing elements perform a linear sliding movement with respect to each other. They are used in hydraulics and pneumatics, for example for sealing linearly guided carriages, trolleys or tables.

Dynamic seals are available in a variety of materials for applications in various fields such as the chemical industry, petrochemicals, and the medical and food industries, as well as the metal industry. First and foremost, the existing pressure difference determines the choice of the suitable seal. The following types belong to the dynamic seals:

- Guide rings

- Rod seals

- Scraper

- Piston seal

Regardless of whether it is a translational or rotational movement, the elements of touch seals for dynamic applications are subject to friction, heating and wear. This means that the contact pressure must not be too high and complete sealing of the components is not possible. In addition, friction and wear - caused, for example, by the opening and closing of seals - cause unevenness on the sealing elements, which can also lead to increased diffusion and permeability.

Non-Contact Seal - Which seals are these?

In addition to contact seals, which constitute the majority of seals, there are also contact-free seals. Known as non-contact seals, they are employed in dynamic applications where very high relative velocities are present, and maintenance is challenging.

Unlike contact seals, non-contact seals do not experience high friction or significant wear - providing optimal conditions for the efficient operation of various systems. Thus, non-contact seals broaden the range of applications in high-speed scenarios, for dynamically sensitive systems, and in systems requiring high levels of cleanliness.

Non-contact seals are differentiated into

- Pressure and throttle seals, and

- Mass force and viscosity seals

These are primarily utilized in the construction of gas, water, and steam turbines. Gap seals, which are categorized as viscosity seals, also fall under the umbrella of non-contact seals. They are typically used in centrifugal pumps, fans, and piston compressors.

Rotary seals (shaft seal rings)

Rotary seals, also known as shaft seals or Simmerrings, are utilized to reduce leakage losses or air intrusion in applications like pumps, thereby minimizing potential wear on the sealing surfaces as much as possible. The use of sealing rings depends on the specific sliding speed, the pressure that needs to be sealed, and the temperature of the medium. Various pump types necessitate different rotary seals, such as single-acting and double-acting rotary seals. These active seal elements are thus produced in a range of designs and variants. A common characteristic of all rotary seals is that the system pressure aids the sealing function.

Shaft seals are used to seal machine housings at points where elements, like shafts or rods, exit, protecting them against external environments. Radial shaft seals are fitted tightly into the housing or cover. Their sealing lip is in contact with the rotating shaft's surface and is typically pressed against the shaft surface radially by a spring. To minimize wear as much as possible, special attention should be paid to the type of sealing material used and the condition of the surface.

Unlike radial shaft seals, axial shaft seals typically seal against a part of the housing in an axial direction. They are employed for minor sealing functions, such as protecting from dust or water spray.

Standard seals at Kofler - Dichtungen to buy online

You can easily purchase your standard gasket online. At Kofler - Dichtungen, quality and customer-centric services are our top priorities. We are committed to fulfilling customer demands knowledgeably, efficiently, professionally, and in a timely manner. Our selection encompasses a wide range of standard and simple seals and gaskets as well as custom-made special seals to ensure you find precisely what your applications require:

|

|

|---|

We cater to a wide range of sectors such as the industrial sector, mechanical and civil engineering, municipal technology, energy technology, mining and tunnel construction, as well as automotive and transportation. Depending on the requirements and tailored to the specific needs, all our seals are available in various sizes, quantities, and materials. Whether you're in need of contact or non-contact, dynamic or static sealing solutions, Kofler - Dichtungen offers the highest quality at competitive prices, complemented by expert advice, all from one source.

Sealing materials for any application

The possible areas of application for seals are numerous and differ in their respective requirements. In order to meet the different requirements of different industries and applications, seals are not only available in different sizes and shapes.

Various materials are also used, which are selected based on their nature and properties for the respective purpose. For example, a sealant made of putty cannot be used for the production of O-rings. The material is simply not designed to be processed into a high-density, annular seal.

During production, therefore, care is taken to use the optimal material advantageously for each field of application, always in such a way that the disadvantages are not significant.

Wide selection of elastomers and materials for seals

Various elastomers are of particular importance here. Elastomers are dimensionally stable but elastically deformable plastics whose glass transition point is below the operating temperature. These include the following:

- NBR

- Viton® (FPM/FKM)

- EPDM

- Silicone: MVQ/VMQ (methyl vinyl silicone rubber)

- FFKM (Kalrez)

- HPU: hydrolysis-resistant polyurethane

- HPU solid: a harder HPU for special applications

- HPU MOS2: a compound of HPU and molybdenum sulfide

- Pom: Polyoxymethylene

- PTFE: Polytetrafluoroethylene (Teflon)

- Peek: Polyetheretherketone

- Foam rubber

Order special seals - manufacture of custom seals

Custom seals and the manufacturing of tailor-made seals present no challenge for us as seal experts. Often, there is a demand for custom sealing solutions designed to meet specific needs and applications. High flexibility, innovative spirit, and our commitment to quality are the perfect foundation for creating individually tailored custom seals. For us, flexibility regarding quantities is just as crucial as ensuring timely, scheduled delivery.

To guarantee smooth operation and punctual delivery, even during pandemics and times of increased delivery durations, we offer quick solutions. We can manufacture and deliver custom seals within a few days, depending on the seal and your location.

Thanks to our in-house seal production and our extensive stock of trade goods, we are supremely adaptable and can provide our customers with a broad and comprehensive range of seals and gaskets. Shape-independent manufacturing methods such as waterjet cutting technology enable us to produce seals ranging from an inner diameter of 1 mm (0,039 in) up to large seals with an outer diameter of 2,500 mm (98 in).

From our extensive inventory of materials, we select the appropriate raw material and the specific profile in consultation with the customer. This approach allows us to rapidly and flexibly meet diverse requirements. The materials we have on hand span a temperature range from -260°C to +1,000°C (-436°F to 1832°F), and we are also open to processing special materials upon request.

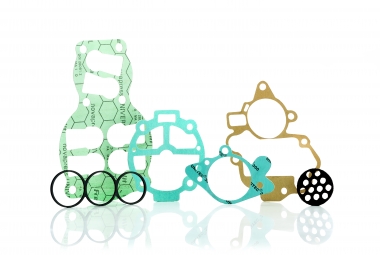

Seal kit development - production of seal kits

A seal set consists of several seals that are coordinated to work together effectively. These sets are utilized in a variety of industrial applications and are available as standard configurations or as sets of custom seals in diverse materials and profiles.

As with individual seals, quality is consistently the highest priority. A seal set or gasket set must be technically reliable and safe, demonstrate durability, and also be economically viable, just like a single seal.

Kofler - Dichtungen creates and produces complete gasket sets for numerous applications. These sets are especially common in hydraulic systems within hydraulic cylinders, where they often withstand extremely high temperatures and pressures and are resistant to aggressive chemicals. Moreover, they are tailored to meet not only the specific requirements of their application but also to accommodate environmental conditions.

Potential applications for hydraulic cylinder gasket sets include:

- Excavators, hydraulic excavators, large hydraulic excavators

- Dump trucks, bulldozers (bulldozers, track dozers), rollers

- Tractors (front loaders), tiltrotators, manure and fertilizer spreaders, seeding and harvesting machines, combine harvesters, plows, and planting machines

- Hydraulic turbines, Pelton, Francis, Kaplan, and propeller turbines

- Bottling systems, hydraulic presses, injection molding

- Lifting booms, bucket cylinders, control blocks, swivel joints

Which seals for which purpose? Application areas and industries for seals

Seals and Gaskets are an indispensable part of our everyday lives. They ensure the reliable functionality of a wide variety of applications and almost every industry, but also every private person, depends on functioning seals.

Defective or porous seals in the household are, for example, the cause of leaky taps or can lead to the refrigerator no longer being able to work properly. They can also lead to defective washing machines or a broken water pipe - and the list could go on and on. In any case, they cause unpleasant and costly failures even in the private sector. One can only guess at the serious consequences of inadequate seals in industry.

Kofler - Dichtungen stands for high-quality seals suitable for any application. For over 30 years, we have supplied customers from a diverse range of sectors both domestically and internationally with our standard seals and bespoke solutions, ensuring seamless operation for each specific application. Our portfolio spans a wide array of seal and gasket types, from O-rings and lip seals to flat gaskets and especially the commonly utilized hydraulic seals.

The industries we serve include:

- Mechanical and vehicle engineering

- The construction and building sector

- Agriculture and municipal services

- Energy technology (including power plants and hydropower stations)

- Mining and tunnel construction

- Transportation

- The wood industry and various other industrial sectors (heavy industry, pharmaceuticals, food processing)

For more than three decades, we have been an innovative, reliable, and adaptable partner for these industries, providing them with standard solutions or collaborating to develop custom-tailored seals designed to meet specific requirements. You can easily add standard profiles to your shopping cart and order directly online. An overview of shipping costs is also provided. Feel free to inquire about your new seal via our contact form. For expedited delivery, we offer our TURBO service.

Your seal ready for pickup within 24 hours

In-house Seal Production: Thanks to our formless production process, we are capable of manufacturing seals ranging from an internal diameter of 1 mm (0,039 in) up to large seals with an external diameter of 2,500 mm (98 in). We select the appropriate raw material and specific profile from our extensive material inventory in consultation with our customers, based on the application area of the seals. This enables us to quickly and flexibly meet the needs of every individual customer.

Extensive Stock of Merchandise: Our sizable warehouse consistently houses approximately 20,000 to 30,000 dimensions of O-rings and shaft seals in a variety of designs. We also have ready access to several thousand sets of seals, flat seals, large seals, and other standard size products. Furthermore, the warehouse stocks dirt scrapers, rod and piston seals, guide rings and strips, support rings, and much more.