-

Homepage

-

Seals and Gaskets

-

Standard Profiles

-

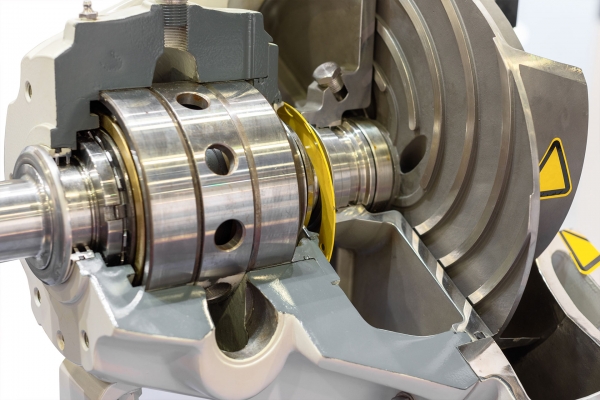

Shaft seal

- Simmerring seal

A Simmerring typically comprises a flexible sealing element and a rigid metal housing that secures the seal in place. The flexible sealing element, oriented towards the movable shaft, is generally made from a high-quality sealing material, chosen based on the requirements, dimensions, and rotational speed of the shaft to be sealed. The use of Simmerrings aims to enhance the efficiency and longevity of mechanical systems by reducing the wear on moving parts and preventing damage caused by escaping or infiltrating liquids or gases. Simmerrings are employed in numerous applications, designs, material combinations, and for various purposes

Simmerring applications

As previously mentioned, Simmerring seals are utilized in a multitude of applications. Below are examples highlighting the diverse application areas for Simmerring seals:

- Engines: In engines, Simmerring seals are employed to prevent the leakage of engine oil or coolant. They are commonly used at the crankshaft, the camshaft, and the oil pump.

- Transmissions: Simmerring seals are incorporated into transmissions to stop transmission oil from leaking. They are frequently placed on the input shaft, the output shaft, and the clutch. Often, Simmerring seals are installed to protect the ball bearings.

- Pumps: To prevent the escape of liquids or gases, Simmerring seals are used in pumps. They are regularly applied to the drive shaft and the pump shaft.

- Compressors: In compressors, Simmerring seals are utilized to avert the expulsion of gases. They typically find their application on the drive shaft and the compressor shaft.

- Engineering: Simmerring seals are deployed in a wide array of machines and equipment to prevent the leakage of fluids or gases. They are also frequently used in the food industry, the chemical industry, and the oil and gas industry.

The potential applications of Simmerring seals are virtually limitless, as they can be integrated into a plethora of mechanical systems. By preventing the leakage of fluids or gases, they contribute to enhancing the efficiency and reliability of machines and equipment. This not only helps in avoiding costly repairs or failures, but also in protecting ball bearings from contamination.

Simmerring materials

Simmerrings, also known as shaft seals, can be made from a wide range of materials suited to their specific applications. Below are some commonly used materials for simmer rings:

- NBR (Nitrile Butadiene Rubber): A prevalent material for rotary seals, noted for its resistance to mineral oils and lubricants.

- FKM / FPM / Viton (Fluorosilicone Rubber): A material resistant to high temperatures and capable of withstanding aggressive substances such as fuels, oils, and chemicals.

- EPDM (Ethylene Propylene Diene Monomer Rubber): Known for its excellent resistance to water, steam, and cold temperatures.

- PTFE (Polytetrafluoroethylene): Distinguished by its outstanding sealing properties and chemical resistance, although it is less flexible than other materials.

- Graphite-reinforced Rubber: Integrates rubber with graphite fibers to enhance sealing and wear resistance.

Selecting the appropriate sealing material involves several factors, including the seal's requirements (e.g., chemical resistance, temperature tolerance), operational conditions (e.g., speed, rotational speed, pressure), and the media being sealed (e.g., lubricants, fluids, sea or saltwater).

At Kofler - Dichtungen, we’re here to offer expert advice on material selection, designs, variants, spare parts, measurements, and installation. Feel free to reach out to us. Because when under pressure, we excel.

What types of Simmerring seals are there?

As already mentioned, there are numerous types and designs of Simmerring seals, each tailored for specific applications and requirements. Below are some of the most prevalent types of Simmerring seals:

Radial Shaft Seals:

These seals are employed to prevent the leakage of liquids or gases along a rotating shaft. Typically utilized in horizontal applications, they feature a circular profile.

Example of Use:

The goal is to seal the junction between a stationary housing and a rotating shaft, ensuring no gases, liquids, or dirt can bypass the seal.

Axial Shaft Seals:

These seals are designed to stop the leakage of liquids or gases in the axial direction. Generally used in vertical applications, they possess a rectangular profile.

Example of Use:

It is crucial to seal the transition from a stationary housing to an axially moving shaft, such as a push rod or hydraulic piston, preventing any gases, liquids, or dirt from breaching the seal.

V-Ring Seals:

Serving as axial shaft seals, these are utilized to block the escape of liquids or gases in rotating applications. Named for their V-shaped design, they act as a sealing lip and dust lip, keeping axially moving shafts, push rods, or pistons free from contaminants.

Cassette Seals or Cassette Sealing Rings:

Representing a highly durable variant of radial shaft seals, these are mounted within a cassette that encloses a so-called sealing labyrinth. Cassette seals, being self-contained and extraordinarily robust, find applications in the heavy vehicle industry, with heavy agricultural machinery, and also in heavy industry, chemical, pharmaceutical, and food sectors.

Cassette seals are distinguished by their superior sealing performance and longevity compared to standard shaft seals.

What is a radial shaft seal

Radial shaft seals are shaft seals used to prevent the escape of liquids or gases from the lateral movement of a rotating shaft. They are made of an elastic material, such as nitrile (NBR), fluororubber (FKM/FPM/Viton) or PTFE, and are equipped with a spring to exert a uniform force on the sealing lip.

Radial shaft seals are predominantly used in rotating machines such as motors, transmissions and pumps to extend their service life and prevent leakage. They are used to sealing rotating shafts of different speeds and temperature ranges.

Radial shaft seals are located between moving and fixed parts or between two parts that move each other. These seals consist of two main components:

A cylindrical outer housing with a tight fit that seals against the housing wellbore and a sealing lip that seals against the shaft both dynamically and statically.

The sealing edge is pressed against the mating surface of the shaft with a fixed radial force.

What is an axial shaft seal

An axial shaft seal, also known as an axial seal or Simmerring seal, is specifically designed for sealing rotating shafts and axles. It is utilized to prevent the ingress of contaminants such as dirt, water, oil, or other fluids into the machinery area, while simultaneously maintaining the system's lubrication.

When contaminants reach the area of the axial shaft, they can damage the lubricant, promote corrosion, and cause premature damage to the bearing. Axial shaft seals offer a preventive solution. These seals are engineered to withstand applications where they are exposed to significant contamination.

There are various types of axial shaft seals, including V-ring seals, metal-encased V-seals, clampable axial seals, and mechanical seals.

Seals like axial shaft seals are essential in sealing technology, particularly in drive technology.

Unlike radial shaft seals, which mainly serve to seal the axis in the radial direction, axial shaft seals operate in the axial direction and offer an effective seal against axial forces. This is relevant for components such as push rods, pistons, and axially moving rods.

Factors in choosing Simmerring seals

Choosing the right Simmerring involves several key factors, including:

1. Application Scope:

The Simmerring must meet the specific demands of its application, such as pressure, temperature range, chemical resistance, and whether it needs to withstand high speeds or merely low friction.

2. Dimensions:

The dimensions of the Simmerring must precisely match those of the shafts and housings to ensure an optimal seal. This includes the outer diameter (housing) as well as the inner diameter (shaft, piston, rod).

3. Material:

The material of the Simmerring should be compatible with the application's requirements, for instance, its resistance to oil, chemicals, and high temperatures.

4. Installation:

The installation method of the Simmerring is a crucial selection criterion, as different installation techniques may mandate specific types of Simmerrings.

Therefore, it's essential to thoroughly understand the specific requirements of the application and consider all of the aforementioned factors to choose the appropriate Simmerring. This ensures optimal sealing efficiency and durability.

At Kofler - Dichtungen, we are always ready to provide advice on any queries you might have.

The Simmerring components

Depending on the type, purpose, and design, a Simmerring consists of the following components:

- Housing: The housing is the outer ring of the Simmerring and is usually made of metal or plastic. The outer jacket is often also made from a stiffer elastomer. Additionally, housings are used as required, made of metal or stainless steel

- Sealing Lip: The sealing lip is the part of the Simmerring that seals the shaft. It is made from an elastic material such as nitrile rubber or fluororubber and is typically reinforced with a spring to ensure uniform contact pressure.

- Dust Lip: The dust lip is the external part of the Simmerring and protects the sealing lip from contamination. The dust lip is also referred to as a protective lip.

- Tension Spring: The tension spring or helical spring ensures that the sealing lip applies a uniform contact pressure on the shaft, facilitating optimal sealing.

- Plastic or Metal Casing: Some Simmerrings may also include a robust plastic or metal casing to enhance the Simmerring's stability and strength. These are also referred to as cassette seals.

The various components of the Simmerring work together to ensure a reliable seal between the shaft and the housing, preventing the ingress of liquids, gases, or contaminants

What should be considered when replacing or installing a sealing ring?

When installing Simmerrings, the following points should be noted:

1. Careful Cleaning:

Both the shaft and the housing must be meticulously cleaned to ensure the absence of contaminants or residues that could compromise the seal's integrity.

2. Proper Alignment:

The Simmerring must be precisely aligned to guarantee optimal sealing. The sealing lip should face towards the liquid or gas that requires protection.

3. Uniform Pressure Application:

It is crucial that the Simmerring is mounted with consistent pressure onto the shaft to secure a reliable seal. An overly loose or tight installation may result in leakage.

4. Use of the Appropriate Tool:

Specific tools are recommended for installing Simmerrings to ensure proper placement and to prevent damage to the sealing lip.

5. Adherence to Installation Instructions:

Following the manufacturer's specific installation instructions is vital to ensure the Simmerring is correctly mounted, and a dependable seal is achieved.

By diligently adhering to these guidelines, optimal sealing and an extended lifespan of the Simmerring can be achieved.

If you have any queries regarding the suitable Simmerring, proper installation, spare parts, or their delivery times - contact us. At Kofler - Dichtungen, we are experts in all things related to seals!

Conclusion

Simmerring seals play a crucial role in a vast array of machines and equipment across numerous sectors, including mechanical engineering, the automotive industry, construction, and more. Their purpose is to contain liquids and gases within a specified area while preventing the intrusion of dirt, dust, and various contaminants.

By fulfilling their sealing duties, these components enhance operational safety and prolong the lifespan of machinery.

In the realm of vehicle construction, particularly with cars and construction machinery, seal rings are essential. They are employed in several critical components such as transmissions, drive shafts, differentials, and axles to ensure a reliable seal. In the absence of these seals, fluids like oil and water could escape uncontrolled, potentially causing significant damage to the machinery.

Overall, Simmerring seals significantly contribute to the safety and efficiency of machinery, making them an indispensable element across many industries. It is crucial that they are carefully selected and properly installed to guarantee their full effectiveness, thus ensuring the seamless and efficient operation of machinery. Contact us to acquire high-quality hydraulic seals.