-

Homepage

-

Sealing knowledge

- The history of sealing technology

The history of sealing technology

Modern sealing technology, with its countless variations of seals, has become omnipresent in our lives: from flat seals and gaskets in piping systems or the O-ring in water connections; to piston seals in your car, and even hydraulic seals in your wood splitting machine, if you own one. (What exactly is a hydraulic seal?)

For virtually every application, there is a high-performance seal made from modern materials. In this text, we aim to deepen your understanding of where sealing technology originated and how it has evolved throughout history.

We will take you on a historical journey from antiquity, through the Industrial Revolution to the present day, showing you that many milestones in human history would not have been possible without sealing technology.

In conclusion, with Kofler - Dichtungen as your partner, you can benefit not only in the present but also stride into the future of sealing technology. Our expertise in sealing will undoubtedly convince you.

Sealing technology – What is it and how has it developed?

Sealing technology – what is it? In general, sealing technology deals with the separation and sealing of two areas and minimizing leaks. In the history of technical progress, sealing technology repeatedly made important contributions that made the development of new inventions possible in the first place.

Perhaps the earliest example of this is the simple sealing of aqueducts and irrigation systems to secure the water and food supply in ancient times. It is also worth mentioning the construction of reliable gasometers and city gas pipes with flat gaskets in the mid-19th century, which displaced heating and cooking with wood and coal.

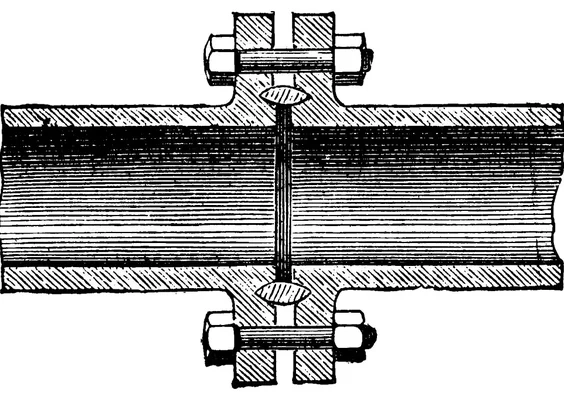

With the industrial revolution and the further development of mechanical engineering, the need arose to also be able to seal moving components. These then new dynamic seals were used in historic water hydraulic forging presses.

Today, countless machines and tools contain powerful seals and entire seal sets, without which their function would not be possible. Examples include hydraulic seals in construction machinery or the modern motor vehicle, e.g. the piston seal in the internal combustion engine and the oil-hydraulic power steering.

The history of sealing technology is thus closely intertwined with the history of mechanical engineering. The progress of sealing technology, for its part, is closely linked to the development of new sealing materials.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

Beginnings of Sealing Technology – Pitch, Leather, and Hemp

In the early days, pitch, bitumen, and hemp or flax fibers were used for static seals, such as in containers, boilers, pipes, and ducts. For dynamic seals, felt was initially used, and from the early 20th century, specially treated leather came into use. Particularly, radial shaft seals made of leather (early Simmer rings) marked a significant advancement in sealing technology.

These materials have a centuries-long application history. They offered adequate functionality for the technology of the time but soon reached their material-technical limits with the development of more powerful machines. Specifically, the production of leather for this purpose became economically unviable due to rising production costs, yet there was no alternative.

Relief came only with the developments in the chemical industry, which from the 19th century onwards provided access to new materials.

Modern Advancements – High-Performance Plastics

The production of elastomers (rubber) by so-called vulcanization of rubber by Goodyear from the mid-19th century was groundbreaking for modern sealing technology. This process allowed access to elastic materials that could be used over large temperature ranges and justified, for example, the development of the tyre and the rubber seal. However, rubber production was dependent on the availability of natural rubber from South America and Southeast Asia. At that time, this raw material was fraught with long delivery times, high transport costs and availability problems in terms of economic policy.

A way out emerged at the beginning of the 20th century with the first production of a fully synthetic artificial rubber by the Russian chemist Ivan Kondakov. In the following decades, numerous new plastics were developed and constantly improved in terms of their material properties. This made it possible to replace leather as a sealing material and heralded the advent of modern sealing technology. The new materials were widely used in machine and tool construction and in the automotive industry. This also made it possible to develop high-performance hydraulic and pneumatic systems (hydraulic seal and pneumatic seal).

The next milestone in the history of sealing technology is the development of silicone and fluorinated rubbers in the USA in the 1940s. These materials showed unprecedented material properties for the time, such as resistance to chemicals, and extended the possible use temperatures.

As before, the material properties are continuously improved through novel raw materials and additives, as well as optimized manufacturing and processing processes.

Do you have any questions?

Current state of sealing technology: in the Kofler - Dichtungen range of seals

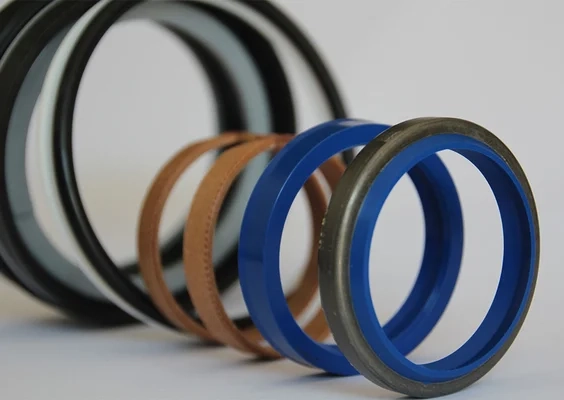

Sealing technology boasts a rich developmental history. Nowadays, we have access to a vast array of materials, enabling the use of various substances for nearly any application.

At Kofler - Dichtungen, we stay abreast of the latest technological advancements, processing and supplying seals and gaskets from the most advanced high-performance elastomer materials:

- PU (Polyurethane)

- PTFE and PTFE compounds enriched with fillers like bronze, coal, or MoS2

- NBR (Nitrile Butadiene Rubber)

- Viton® (FKM / FPM) Fluoroelastomer

Our product lineup includes seals and sealing elements suitable for a wide array of applications:

- Scrapers

- Guide rings

- Rod seals

- Piston seals

- Support rings

- O-rings

- Rotary seals

Depending on the specific application, we offer these components in diverse profiles and sizes ranging from 4 mm to 2,500 mm. We are eager to consult with you regarding the most effective combination of profile and material, ensuring you receive the ideal seal and gasket for your needs.

Tread the path to the future with seals and gaskets from Kofler - Dichtungen

History continues to be written in the field of sealing technology. Engineers and researchers from around the globe develop new materials and work on enhancing existing ones. This results in continuously improved material properties, evident in an expanded range of applications (including temperature extremes, harsh, dirty outdoor conditions), increased pressure resistance, chemical resistance, and a longer lifespan.

At Kofler - Dichtungen, we are and will continue to be experts in sealing technology. We constantly keep you updated, ensuring we can offer you the most advanced sealing technology promptly. Partnering with us means you always benefit from the latest state of the art.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."