-

Homepage

-

Sealing knowledge

- O-Ring Materials - Elastomers you should know about

O-Ring Materials - Elastomers you should know about

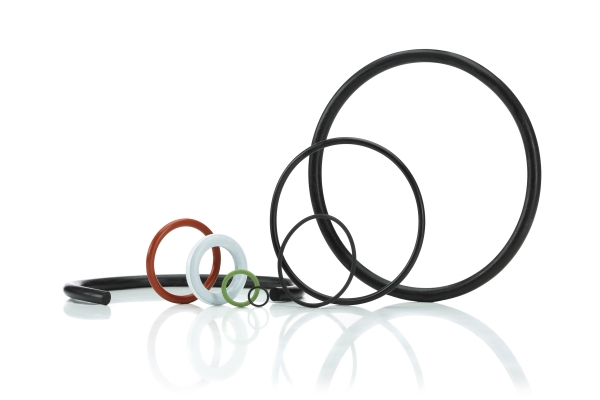

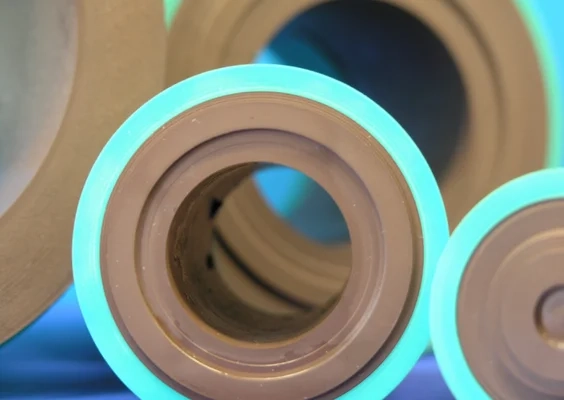

O-Ring seals and industrial seals for commercial use are typically made from industrial plastics or vulcanized rubber. Regardless of whether they are standard profiles or special seals with unique dimensions, high-quality elastomers are always utilized. The choice of elastomer depends on the specific requirements and application. Kofler - Dichtungen also designs and manufactures a complete seal set from various elastomers. At Kofler - Dichtungen, we are your go-to source for sealing knowledge and expertise in industrial seals.

What are elastomers?

Elastomers are dimensionally stable plastics, but they are elastically deformable and highly resilient in order to meet the requirements of industry. While these plastics can deform elastically under tensile and compressive loads, they then return to their original, undeformed shape. Compression set for elastomers. According to DIN 53 517 or DIN ISO 815 or ASTM D 395, the compression set (DVR) is measured at constant deformation.

In addition, they cannot be melted even at high temperatures, but they may have thermoplastic properties. These features make elastomers the first choice in sealing technology and the production of sealing rings for industry and commerce. When it comes to O-ring material selection, it naturally helps to know which elastomers are available and what properties distinguish them from each other.

In the following article, we have therefore compiled an overview of the most important and common elastomers (and also a technical plastomer) for the production of O-rings. After this, you will know how to find the right O-ring seal.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

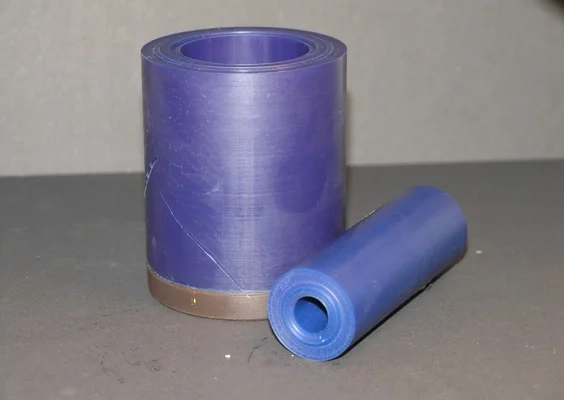

PU - Polyurethane

Polyurethane, also known as PU or PUR, is distinguished by its toughness and high mechanical strength. It is also extremely wear-resistant and resistant to a wide range of mineral oils and greases.

This material is highly abrasion-resistant and, due to its damping properties, it is utilized in the manufacturing of O-rings for hydraulic fittings, valves, pneumatic tools, or cylinders.

NBR - Nitrile Rubber

Nitrile rubber, or NBR, is suited for applications with specific resistance and temperature requirements. NBR is the most frequently used material for O-rings due to its versatility. In the industry, NBR is available in various hardness levels, with the most common being 70° Shore A and 90° Shore A.

While O-rings made from NBR 70° are the most prevalent and are deployed almost universally, NBR 90° O-rings are utilized in high-pressure situations and in installations where a support ring is not permissible.

EPDM - Ethylene Propylene Rubber

Ethylene-propylene rubber, also EPDM, can withstand temperatures from -40 °C (-40 °F) to a maximum of 150° Celsius (302 ° Fahrenheit). O-ring seals made of ethylene-propylene are used for steam, water, brake fluids, alcohols and silicone fluids.

However, O-rings made of EPDM are not gasoline resistant, which is why they are not recommended for use in contact with gasoline, mineral oil and lubricants, as well as hydrocarbon environments. For example, an O-ring made of FKM Viton is suitable here. In addition, O-rings made of EPDM are ozone and weather resistant. EPDM is preferably used to manufacture rubber O-rings for the aerospace industry.

The above information applies to the usual sulphur-crosslinked EPDM. In addition to this crosslinking, there are also O-rings made of peroxidically crosslinked EPDM, which is suitable for the food and pharmaceutical industries.

Viton® FKM - Fluoroelastomer

Viton® FKM (fluoroelastomer), formerly known as FPM, is becoming increasingly important in the sealing industry due to its extensive chemical resistance, high temperature range, low compression set, and excellent aging properties.

This carbon-based polymer is distinguished by its resistance to mineral oils and lubricants. O-rings made of FKM, which are resistant to lubricants and diesel, are deployed in airplanes, automobiles, and other mechanical devices that demand maximum resistance to high temperatures and various fluids. Its notably high shrinkage rate also makes FKM suitable for high-vacuum applications.

Moreover, its good resistance to acids and bases makes it the ideal material for the chemical and heavy industries.

FDA-certified elastomers

Materials certified by the U.S. Food and Drug Administration (FDA) are considered food-safe and non-toxic. These are important prerequisites, especially when such materials are employed in the food or pharmaceutical industries.

The FDA is acknowledged as a global authority on approvals and certifications. It examines materials, types, and constructions. Kofler - Dichtungen exclusively utilizes high-quality elastomers for its O-ring seals, which are FDA-certified when necessary, to fulfill the standards and requirements of these sectors.

Because only by supplying the correct seal the customer can achieve the required quality. All available seals and gaskets can be found in our O-Ring online shop. We also provide custom-made products upon request.

Recently, there has been an increasing demand in Europe for the European food approval EC 1935/2004, which Kofler - Dichtungen also offers increasingly.

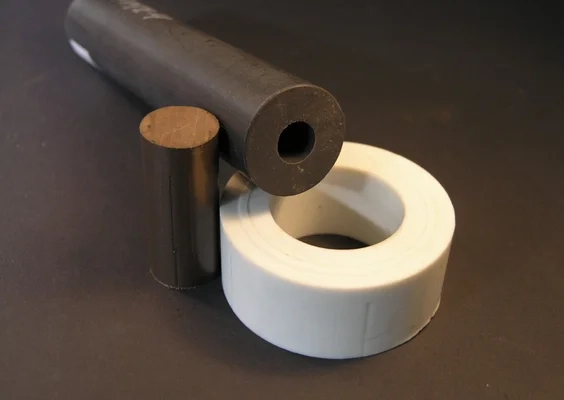

PTFE - Polytetrafluoroethylene

Although PTFE (polytetrafluoroethylene) is not an elastomer but a technical plastomer, it is essential to include this material in any list of O-ring materials!

PTFE is known for its rigidity and delivers excellent results in static applications. Furthermore, it is chemically very inert, typically suitable for food contact, impermeable to many gases, and exhibits minimal absorption.

Due to these characteristics, PTFE O-rings are especially well-suited for use in the food and pharmaceutical industries, as well as the chemical industry. At Kofler - Dichtungen, you can find PTFE seals in various colors and variations.

Get in touch with us!

We perform best under pressure! Personalized advice for the highest demands and a fast delivery guarantee ensure your satisfaction. Contact our sealing experts.

We look forward to your inquiry."

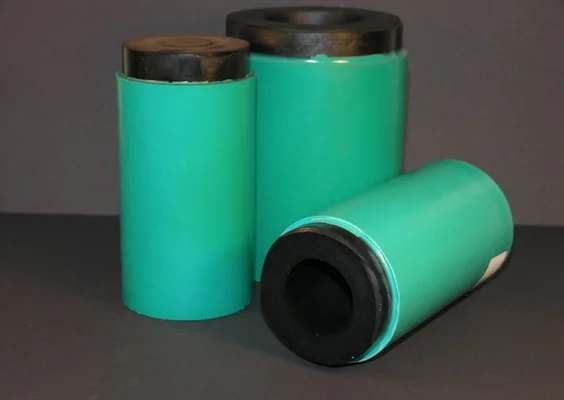

FEP – PTFE-Coated O-Rings

There are O-rings made from FKM or EPDM with an FEP or PTFE coating. These combine the high media resistance of FEP and PTFE with the elasticity of FKM and EPDM.

Such material combinations are used in highly demanding applications, for instance, where the chemical resistance of PTFE is required, but a solid PTFE O-ring would not be sufficiently elastic.

Kofler - Dichtungen also offers solutions for hydraulic seals and pneumatic seals. Learn more about what exactly hydraulic seals are.